Carboneto de tungstênio de alta resistência à corrosão

O que é carboneto de tungstênio resistente à corrosão?

Para resolver os problemas do carboneto de tungstênio durante o processamento WEDM, criamos carboneto de tungstênio anticorrosivo usando ciência e tecnologia de materiais de ponta. Esse melhora isso é estabilidade e resistência para corrosão, significativamente aumentando mofo serviço vida.

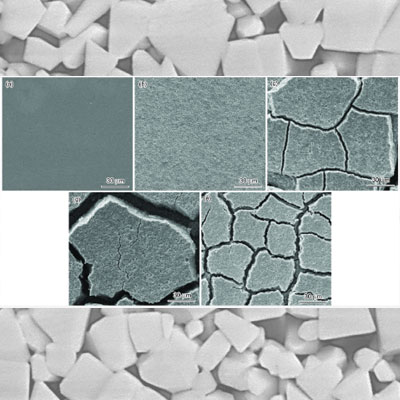

O princípio de anti–corrosão envolve misturando carboneto cru elementos (como crômio, vanádio, molibdênio, nióbio, etc.) com anti–corrosão Propriedades em o pó dosagem durante o preparação estágio. Esse previne corrosão de ocorrendo. Quando o carboneto cimentado resistente à corrosão entra em contato com um corpo corrosivo, os elementos raros funcionam como um escudo protetor, criando uma fina camada de óxido protetor que isola a superfície do carboneto do ambiente ao redor, impedindo assim o progresso da corrosão. Como o elementos são uniformemente misturado, o proteção é contínuo e não afetado por usinagem, prevenindo isto de vestindo desligado.

O benefícios de usando corrosão–resistente carboneto material incluir:

1. Mais baixo custos para filtragem o médio (água) durante arame corte.

2. Redução de custos associados a processos adicionais e redução de qualidade resultante da corrosão na peça de trabalho.

3. Mantém o brilho da superfície e evita seções transversais microscópicas que podem levar ao desgaste mais rápido da matriz ou à formação de rachaduras.

A resistência à corrosão do carboneto cimentado é um fator crucial para matrizes de estampagem e punções submetidos à usinagem por descarga elétrica. Devido às finas rachaduras que não são visíveis a olho nu produzidas pela usinagem por descarga elétrica, a ciência e a tecnologia avançadas de materiais foram utilizadas para adicionar outros carbonetos ao carboneto de tungstênio e ao carboneto de tungstênio-cobalto. Isso resultou em uma resistência à corrosão melhorada para o carboneto de tungstênio durante a descarga elétrica e uma redução nas microfissuras.

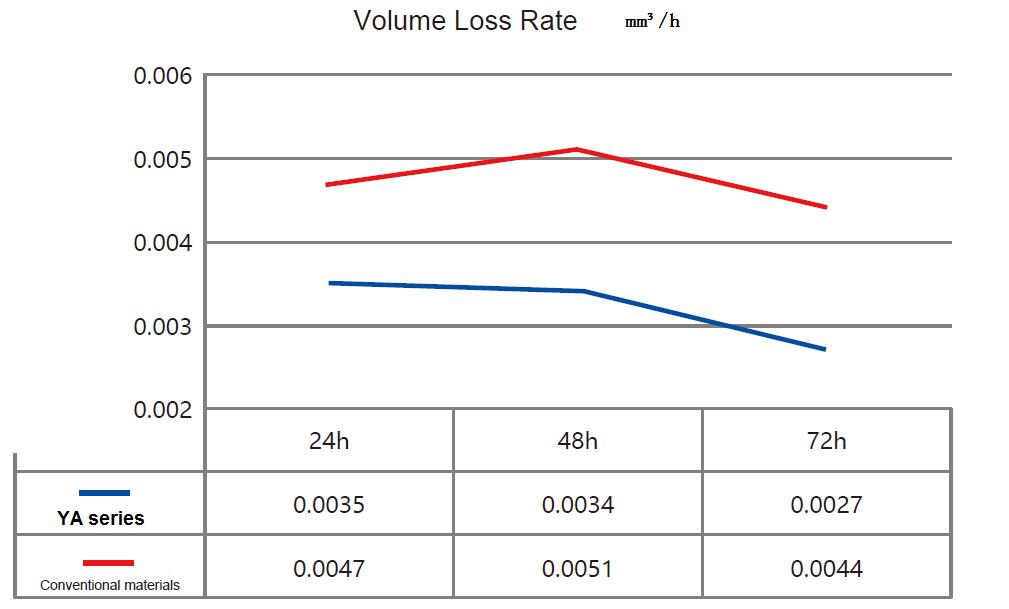

Resultado do teste de resistência à corrosão com método de perda de peso em solução de HCl 10%

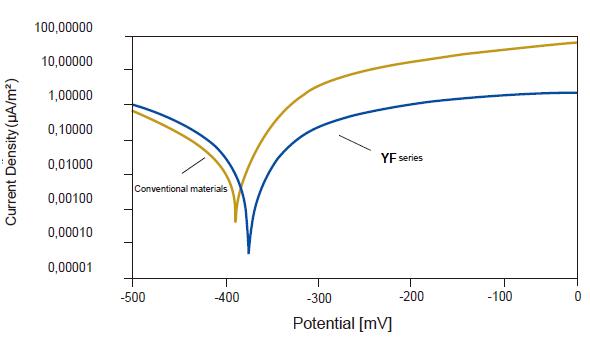

Resultado do teste de corrosão eletroquímica

Os dois resultados dos testes mostram que a resistência à corrosão do 5o carboneto de geração foi significativamente melhorado. Antes que o cobalto ligante seja decomposto, o material resistente à corrosão produzirá continuamente uma camada protetora, reduzindo assim muito a taxa de corrosão.

Escolha nosso Metal Duro para fazer seu matrizes de estampagem duram mais, são mais estáveis e custam menos.

Mais informações para Blocos EDM de metal duro