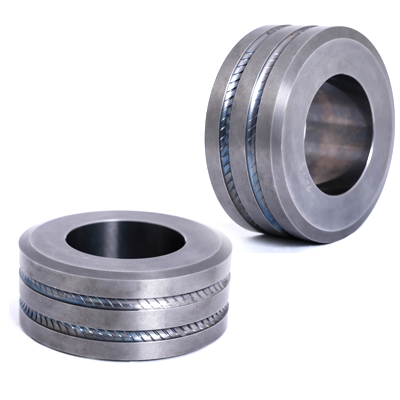

Tungsten Carbide rolls

YATECH MATERIALS supplies first-rate tungsten carbide roller rings in China, specifically engineered for exceptional performance in rolling cages at speeds ranging from 2-120 m/s, making them ideal for pre-finishing and finishing.

Our cutting-edge tungsten carbide technology ensures suitability for both hot and cold rolling at temperatures of up to 800℃. We provide 24-hour technical support, and our product specialists offer skilful advice on cemented carbide grades, roll handling, machining data, and roll performance evaluation.

At Yatech, we are dedicated to enhancing your productivity. Our team of specialists is accessible to aid you in developing and enhancing your production process. Our robust tungsten carbide rolls are manufactured in adherence to the highest standards of quality, guaranteeing outstanding durability and wear resistance.

Tungsten Carbide Roller Ring Solutions

In brief, Yatech’s tungsten carbide roller rings are the perfect choice for any rolling application. With state-of-the-art technology, top-notch quality control, and devoted support from our team of specialists, you can rely on us to assist you in achieving your production objectives.

Apart from our exceptional product performance and excellent technical assistance, we also place great emphasis on providing outstanding customer service. Our aim is to ensure a smooth experience from the outset of your request to the ultimate delivery of your tungsten carbide roller rings.

We acknowledge that our clients’ needs and demands are distinctive, therefore, we endeavour to satisfy them with flexible solutions and customised care. Our experienced team is easily accessible to answer any inquiries and resolve any problems.

If you’re searching for top-notch tungsten carbide roller rings for your rolling application, Yatech is the ultimate solution. Contact us now to obtain in-depth information regarding our products and services.

Carbide Rolls Grades

| Grade | Binder % | Grain Size μm | Density g/cm^3 | Hardness HRA | T.R.S N/mm^2 | Application |

| YGR20 | 10.50% | 3.0 | 14.5 | 84.0 | 2400 | 13-14 Finishing rolling 17-18 Reducing/Sizing Mill |

| YGR30 | 15% Co+Oth | 3.0 | 14.0 | 84.5 | 2350 | 10-12 Finishing rolling |

| YGR40 | 18% Co+Oth | 3.0 | 13.7 | 83.0 | 2200 | 8-9 Finishing rolling |

| YGR45 | 20% Co+Oth | 3.2 | 13.6 | 82.0 | 2150 | 5-7 Finishing rolling |

| YGR55 | 25% Co+Oth | 3.2 | 13.1 | 79.5 | 2100 | Pre-Finshing Mill 1-4 Sorties |

| YGR60 | 30% Co+Oth | 3.5 | 12.65 | 77.5 | 2000 | Inter mediate Mill Screw thread Steel Bars |

Types of carbide roller rings

Our ability to manufacture tungsten carbide roll rings

There may be additional types of rolls that are not illustrated, and we are capable of manufacturing the carbide rolls you require based on the drawings you provide. Our maximum dimensional tolerances reach up to 0.002μm, and we achieve extremely high surface roughness.

Kindly inform us if you have any particular prerequisites or inquiries regarding the carbide rolls. We are delighted to offer supplementary details and explore how we can fulfil your requirements. Our team of professionals is readily available to help you streamline your production processes and achieve your production targets. Contact us today to discover more about our range of products and services.

High-speed wire rod mill with Yatech Materials carbide roll ring, better stability, higher efficiency.