Tungsten Carbide Fastener Blanks for Cold Heading Dies Blanks

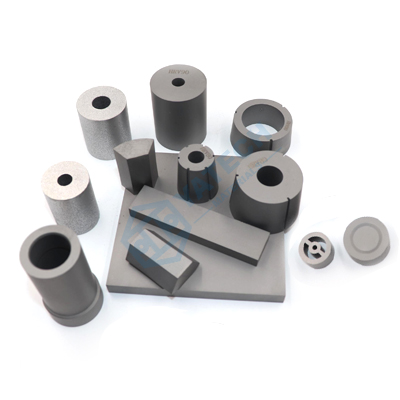

Our R&D engineers use a combination of coarse and fine grain tungsten carbide powders and a high cobalt content formula to produce cold heading dies with better impact resistance and wear resistance.

It can better prevent the cracking of cold heading dies, achieve better working conditions and improve the efficiency of cold heading.

The failure mode of fastener dies is cracking, we have developed impact resistant carbide for fastener dies.

Advantage

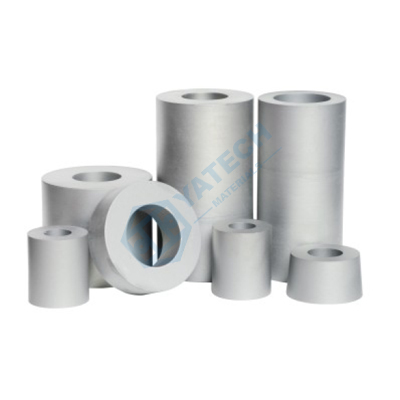

Reliable carbide tooling material for bolt, screw and nut forming.

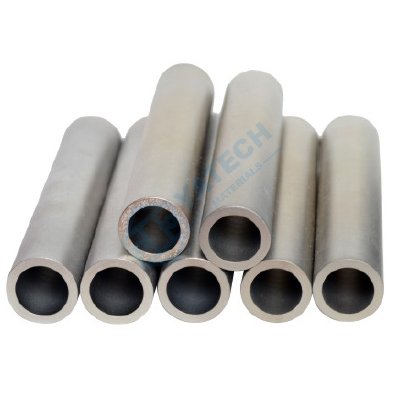

Long life carbide grades to meet industry requirements for extrusion applications.

Higher yields with premium carbide.

Higher yields with custom tolerance options.

Fast delivery, production cycle 3-5 days.

You can choose Air Express to reach anywhere in the world at the fastest speed.

We have a wealth of experience in fastener forming tools and continue to develop materials for cold heading tools with improved wear resistance and toughness, including a range of grades specifically for forming stainless steel fasteners.

We are committed to providing products that meet our customers’ requirements.

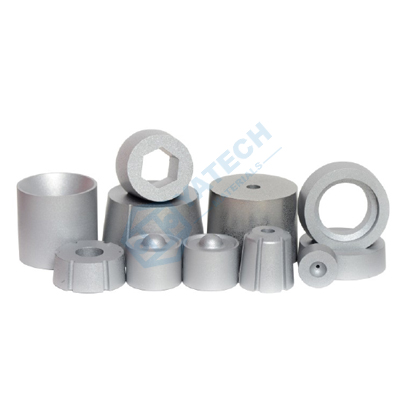

Fastener forming cores, coated cold heading dies, custom fastener dies and more.

Grade

| WC Grain Size | Grade | Co% | Density g/cm3 | Hardness HRA | T.R.S GPa | Applications |

| Medium | CG5 | 12 | 14.3 | 88.3 | 3300 | High toughness cold heading dies |

| CG6 | 14 | 14.12 | 87.3 | 3140 | ||

| Coarse | CA18 | 18 | 13.75 | 85.1 | 2940 | Screw mold with aperture below Φ20 |

| CA24 | 24 | 13.25 | 82.5 | 2650 | Screw mold Φ20 - Φ50 | |

| CT15 | 15 | 13.8 | 86 | 2700 | Stainless steel screw die with aperture below <Φ2 | |

| CT20 | 20 | 13.6 | 84.5 | 2660 | Stainless steel screw die with aperture above >Φ2 | |

| CA20 | 20 | 13.55 | 84.1 | 2740 | Warm/hot forging dies |