Ideal Choice for Precision Stamping Progressive Dies

Designed specifically for precision stamping dies, offering high accuracy and consistency, ensuring die life and product quality.

Ultra-High Hardness and Wear Resistance: Superior performance of WC+Co+other carbide hard alloy, capable of handling high loads and extended use, extending die life and reducing production costs.

Outstanding Corrosion Resistance: Resists various corrosive media, ensuring the die operates normally even in harsh environments.

Low Stress Characteristics: Reduces stress during die processing, minimizing deformation and cracking, ensuring die accuracy.

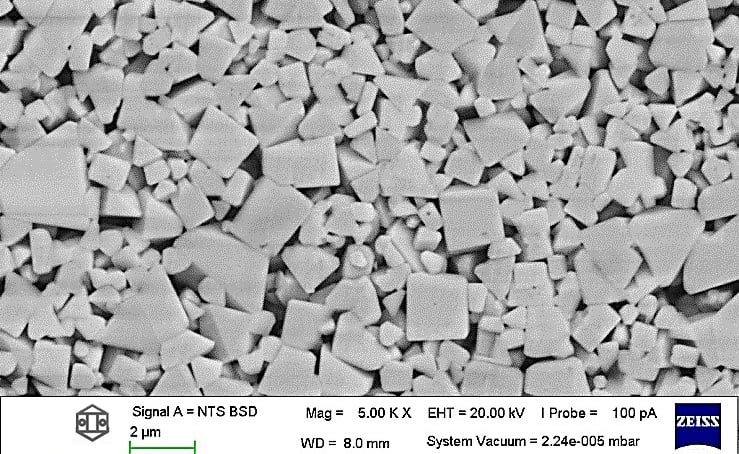

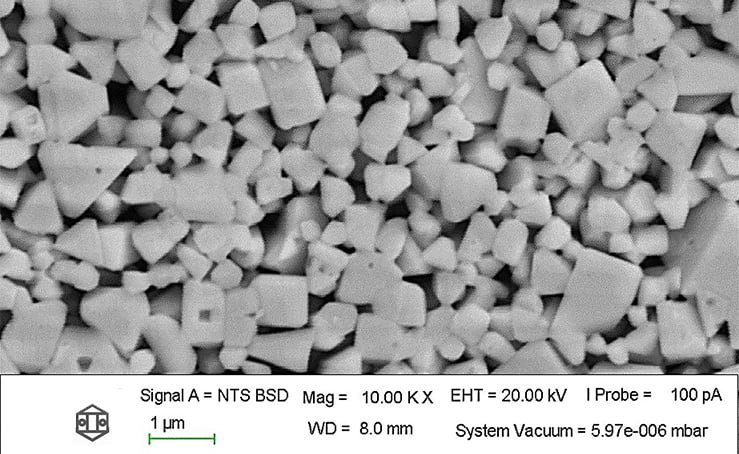

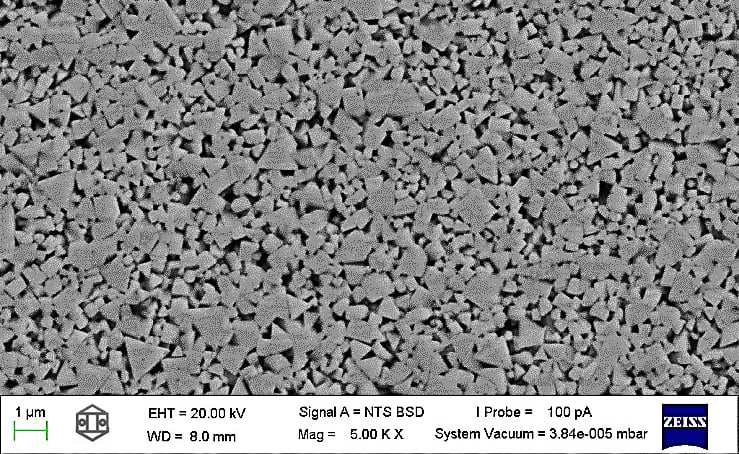

Double Crystal Structure: Unique structure enhances the strength and toughness of hard alloy, effectively improving the durability and reliability of the die.

Exceptional Impact Resistance: The toughness of hard alloy withstands the impact forces during stamping, preventing die damage.

- Customizable Service: Offers customized products and services based on specific customer requirements.

- Technical Support: Provides professional technical advice and after-sales service to assist customers in resolving issues during use.

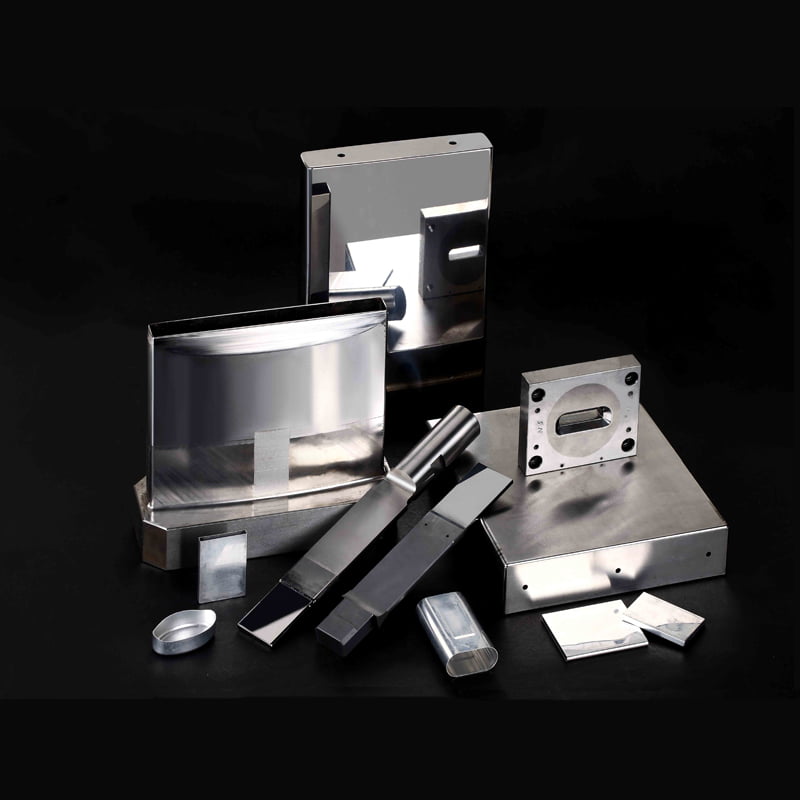

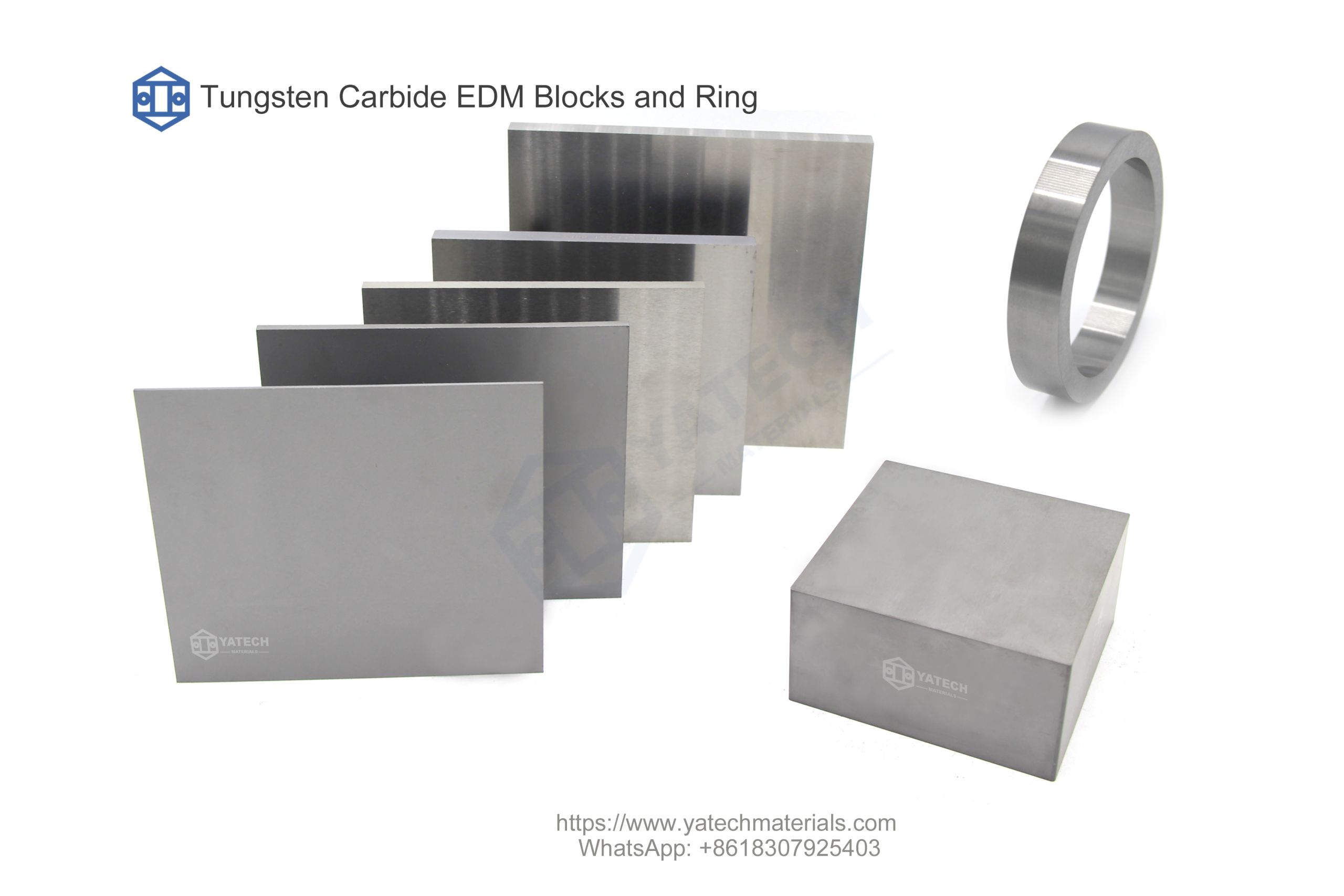

What are Tungsten Carbide EDM Blocks Use for?

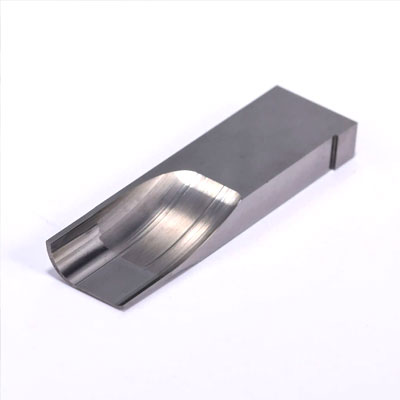

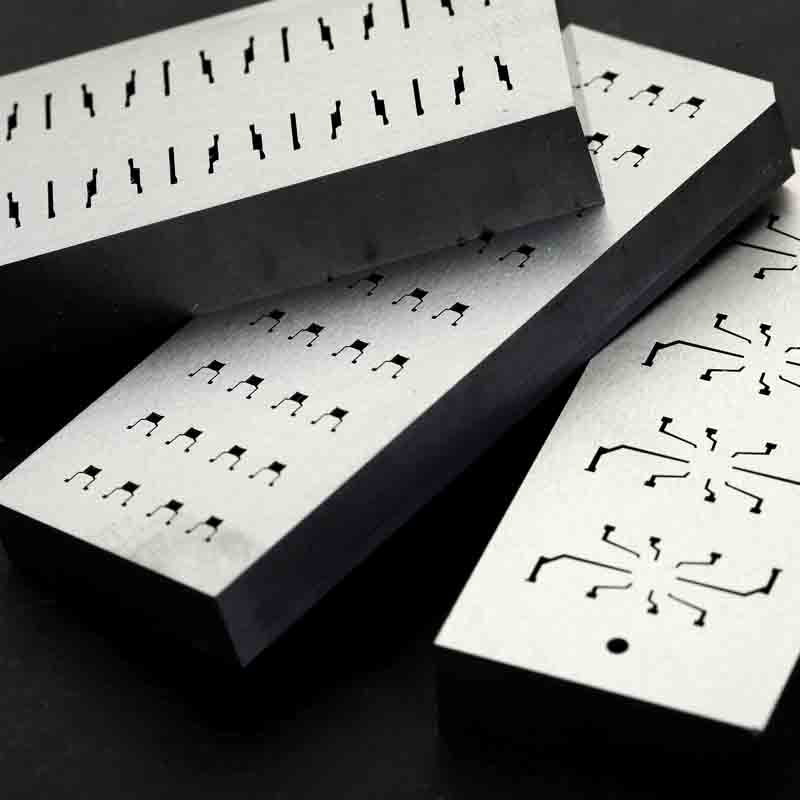

Tungsten Carbide Blocks (Stress Free EDM Blocks) using electrical discharge machining to make Punches, Inserts, Buttons, Blanking, Precision carbide die stamping parts .ect.

The use of Cemented Carbide on appropriate tools can significantly improve efficiency and reduce costs by increasing tool lifespan, stability, and dimensional accuracy.

Tungsten Carbide EDM Blocks for Progressive Stamping Dies

Tungsten Carbide for Auto Stacked Tool & Auto Skewed Rotor Tool & Stator Stamping Tool.

EDM Wire Cutting Blanking & Forming Tools, Carbide Blanks, Carbide Preform Stripper, Carbide Ring.

We offer corrosion resistant carbide suitable for EDM, providing you with high quality solutions.

Our tungsten carbide is designed for various punching materials, including: silicon steel sheet, SPCC, iron strip, beryllium copper strip, stainless steel, and beryllium copper.

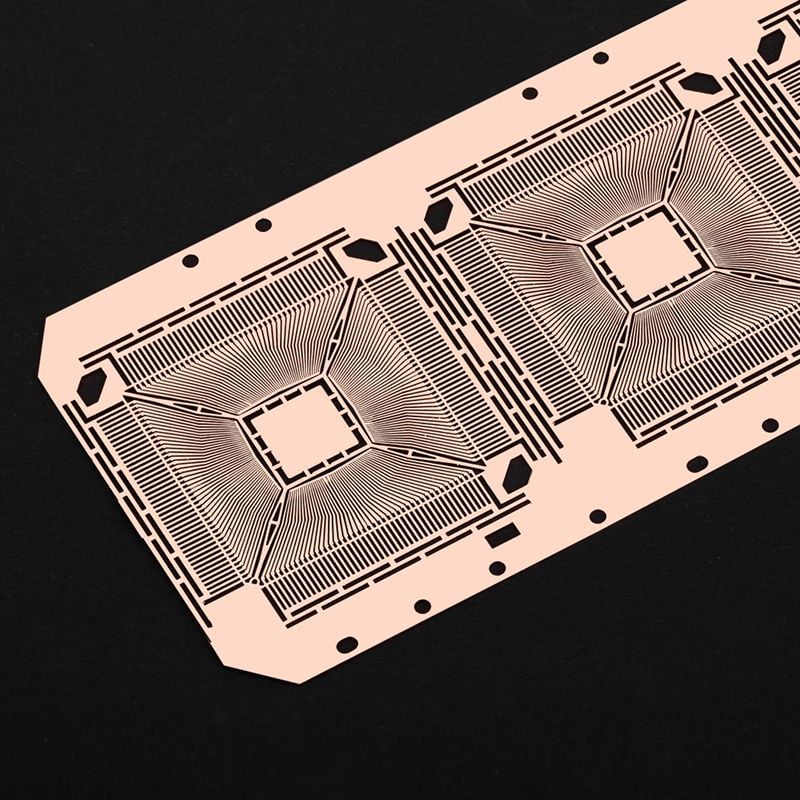

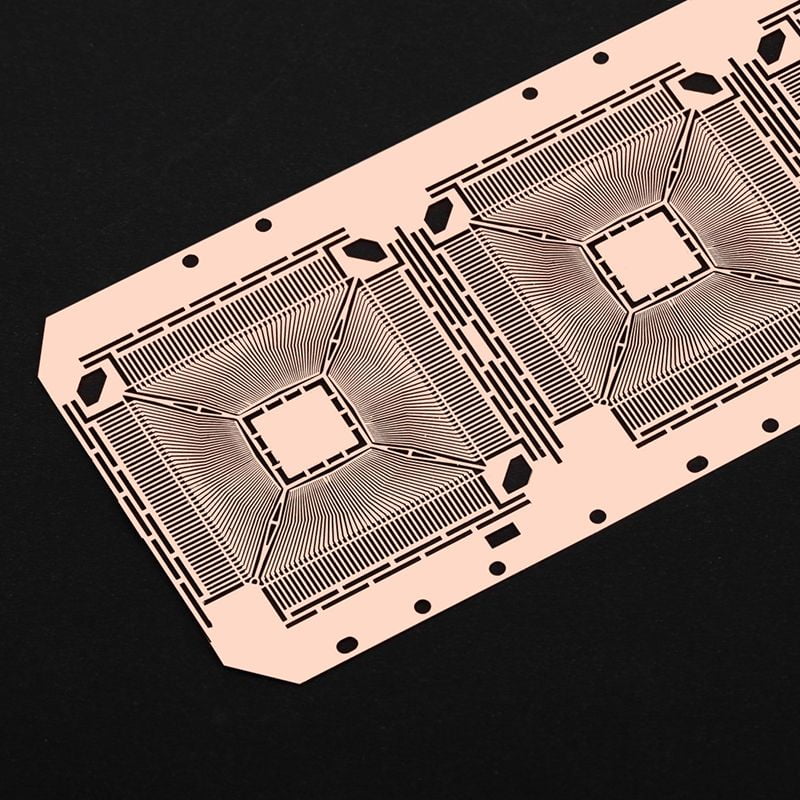

It has received unanimous praise from the stamping die company for products such as motor cores, EI cores, LED brackets, lead frames, connectors and connectors, and has been unanimously recommended by OPG(Optical profile grinder) parts processing plants.Material advantages: high hardness, high strength, high wear resistance, sharp cutting edge, suitable for precision high-speed progressive dies with stamping speed of SPM300-2000 per minute or more.

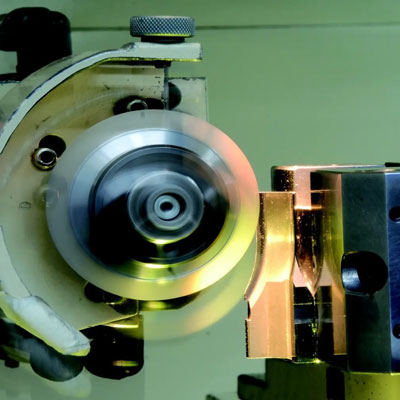

Tungsten Carbide Technology for Stamping Tools

- Corrosion resistant tungsten carbide EDM block.

- Add chromium, tantalum and other complex carbides to enhance the double grain tungsten carbide wear resistance and better impact resistance – longer life.

- Cold isostatic pressing + HIP sintering (1450°C) for more uniform density – more stable.

- Tempering + deep cold treatment (-200 degree Celsius), less stress – avoid cracking.

- Double endface grinding treatment to reduce wire cut cracking due to sintered microcracks.

Explanation of Carbide EDM Block Grades

We use primary tungsten carbide powder, unlike other carbide manufacturers, which guarantees the highest quality of tungsten carbide throughout the entire machining process and maximises consistent performance for the end user.

Corrosion-resistant binder grades optimised for WEDM processes Excellent wear resistance and high edge sharpness.

YF series

Composition: 10%-16.5% cobalt binder with submicron grain structure for stamping tools is designed for heavy-duty applications. It has a medium cobalt content and a blended tungsten carbide powder grain size for enhanced impact resistance, improved vibration resistance and corrosion resistance. This reduces corrosion and debris on the finished carbide surface.

Applications: Stamping dies for laminations, spring steel stampings, coining dies, motor cores, silicon steel sheets and high speed metal stampings.

YA series

Composition: 12%-15% corrosion-resistant binder mix with submicron grain structure, good general properties and toughness, medium cobalt and fine grain hard material. High wear resistance and good chipping resistance. Good electrical machinability.

Applications: YA series is ideal for high-speed stamping of SPCC, steel strip, beryllium copper strip and 304 stainless steel electronic components.

This series is well known in the leadframe and connector industries and is therefore recommended for PG component manufacturing.

lead frames, connectors, LED holders, high speed precision stampings.

YU series

Composition: 10%-12% corrosion-resistant binder with 0.4-0.8μm submicron grain structure. Very good wear resistance with high edge sharpness.

Applications: grades for case stretching dies, such as electric car battery case 18650 21700, 46800, round or square. Also suitable for micro motor case stretching die.

EDM Block Grades Physical Properties

| Series | Grade | Cobalt content Co% | Density (g/cm³) | Hardness (HRA) | KIC (MNm-3/2) | T.R.S (MPa) | Compression Strength (MPa) | Young's modulus (GPa) | Grain Size (μm) |

| YF | YF22H | 10.0 | 14.35 | 89.0 | 14.5 | 3400 | 4500 | 550 | 2.0-5.0 |

| YF30P | 12.0 | 14.15 | 90.0 | 12.5 | 3600 | 4900 | 580 | 1.0-2.0 | |

| YF40H | 12.5 | 14.20 | 89.5 | 13.5 | 3700 | 4700 | 570 | 1.0-2.0 | |

| YF50H | 14.0 | 14.00 | 88.5 | 14.5 | 3800 | 4600 | 550 | 1.5-3.0 | |

| YF55HH | 16.5 | 13.80 | 87.4 | 15.5 | 3500 | 4200 | 540 | 1.0-4.0 | |

| YA | YA50 | 15.0 | 13.95 | 90.5 | 17.0 | 4000 | 4800 | 580 | 0.6-0.8 |

| YA47S | 12.0 | 14.20 | 91.3 | 14.2 | 3800 | 4600 | 550 | 0.6-0.8 | |

| YA40S | 10.0 | 14.45 | 91.8 | 12.6 | 4000 | 4800 | 580 | 0.6-0.8 | |

| YA10H | 6.0 | 14.85 | 90.5 | 13.0 | 3000 | 5200 | 620 | 0.5-5.0 | |

| YA18 | 12.0 | 14.17 | 89.2 | 13.5 | 3600 | 5500 | 570 | 1.0-2.0 | |

| YA20 | 13.5 | 14.05 | 90.0 | 12.0 | 3700 | 5300 | 560 | 0.5-1.5 | |

| YA30 | 12.0 | 14.15 | 91.2 | 10.5 | 3600 | 5400 | 590 | 0.4-0.8 | |

| YU | YU20 | 10.3 | 14.40 | 91.5 | 10.5 | 3800 | 5600 | 600 | 0.8 |

| YU25UF | 12.0 | 14.05 | 92.2 | 8.5 | 4400 | 6000 | 570 | 0.5 |

Recommendations for the use of carbide grades for stamping dies

Confirmed by many precision high-speed die makers and users.

| Stamped Material | Thickness (mm) | SPM Stamping speed/min | Punch | Dies | Remark |

| Alloy Copper | <0.3 | 400-1500 | YA30/YA50 | YA30/YA50 | Best |

| <0.5 | 150-1500 | YA50/YA20 | YA20 | General | |

| 0.5-1.0 | 100-300 | YA18 | YA18 | Thick material | |

| Stainless steel | <0.2 | 400-1200 | YA30 | YA20 | Best |

| 0.2-0.5 | 300-800 | YA30/YA18 | YA18 | - | |

| 0.5-1.2 | 100-500 | YA18 | YA18 | - | |

| Pure Copper Pure Iron | <0.6 | 200-600 | YA30/YF22 | YA20 | - |

| Silicon Steel Sheet | <0.3 | 100-400 | YF40H | YF50H | |

| <0.5 | 100-300 | YF50H | YF55H |

Carbide Standard Blocks (mm)

*Standard Size Carbide EDM Blocks in Stock

| L (+0.6-+2.0) | W (+0.6-+2.0) | H (+0.2-+0.5) |

|---|---|---|

| 105 | 105 | 1.5-60 |

| 125 | 125 | 1.5-60 |

| 150 | 150 | 1.5-60 |

| 205 | 205 | 15-40 |

| 255 | 255 | 15-40 |

| 305 | 305 | 15-40 |

The cemented carbide series developed by us are mainly used in various high-precision stamping dies, high-precision connector terminal stamping dies, chip lead frame dies, LED bracket dies, high-precision multi-station dies, etc.

Cemented Carbide Solution Partners

Carbide EDM Blocks Stock List

| Size L*W*H | Grade | |||

| YA20 | YA30 | YA20N | YF40H | |

| 125*112*1 | R | |||

| 125*112*1.5 | R | |||

| 125*112*2 | R | R | R | |

| 125*112*2.5 | R | R | R | |

| 125*112*3 | R | R | R | R |

| 125*112*3.5 | R | R | R | |

| 125*112*4 | R | R | R | R |

| 125*112*4.5 | R | R | R | |

| 125*112*5 | R | R | R | R |

| 125*112*5.5 | R | R | R | |

| 125*112*6 | R | R | R | R |

| 125*112*6.5 | R | R | R | |

| 125*112*7 | R | R | R | R |

| 125*112*7.5 | R | R | R | |

| 125*112*8 | R | R | R | R |

| 125*112*8 .5 | R | R | R | |

| 125*112*9 | R | R | R | |

| 125*112*9.5 | R | R | R | |

| 125*112*10 | R | R | R | R |

| 125*112*11 | ||||

| 125*112*12 | R | R | R | |

| 125*112*13 | R | |||

| 125*112*14 | R | |||

| 125*112*15 | R | R | R | |

| 125*112*16 | R | |||

| 125*112*17 | R | |||

| 105*105*18 | R | R | ||

| 105*105*20 | R | R | R | |

| 105*105*22 | R | R | ||

| 105*105*24 | ||||

| 105*105*25 | R | R | R | |

| 105*105*28 | R | |||

| 105*105*30 | R | R | ||

| 105*105*35 | R | R | ||

| 105*105*40 | R | R | ||

| 105*105*45 | R | R | ||

| 105*105**50 | R | R | R | |

| 105*105*52 | R | R | ||

| 105*105*53 | R | |||

| 105*105*55 | R | R | R | |

| 105*105*56 | R | R | ||

| 105*105*57 | R | |||

| 105*105*58 | R | R | ||

| 105*105*60 | R | R | ||

| 105*105*62 | R | |||

| 105*105*65 | R | R |

Contact Us

High-speed stamping wear-resistant solutions, carbide processing, carbide usage issues, carbide inventory, how to buy carbide, etc.