Concrete Roof Tile Tooling

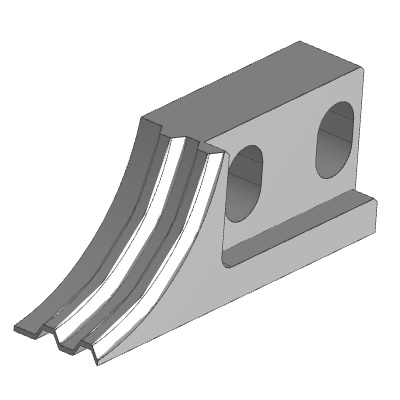

Yatech Materials has developed appropriate carbide wear components for the construction sector, featuring corrosion resistance, high wear resistance, and prolonged wear life.These are utilised in the manufacture of concrete roof tiles, including:

- Rollers

- Slippers

- Water Channels

- Cheek plates

- Lock blocks

- Pusher tips

- Wear plates

what is carbide Roof Tile Tooling

Carbide roof tile tooling involves the use of carbide materials in the production of tools for creating roof tiles. Carbide is a durable material that comprises carbon and other metals, such as tungsten, titanium, or cobalt.

Advantages of Carbide Tools

Compared to other materials, Tungsten carbide roof tile tooling is preferred due to its high resistance to wear and its ability to maintain sharpness for extended periods. This means that manufacturers of roof tiles can use their tools for a longer period before having to replace them, lowering costs and enhancing productivity. Furthermore, the utilization of carbide in the tooling for roof tiles results in a consistently high-quality finish that is precise, ensuring the tiles fit together perfectly and provide outstanding protection against the elements.