Tungsten Carbide Rods, Solid Carbide Rods

Tungsten Carbide Rod Blanks

Consistent Quality

Our carbide rods are highly regarded by our customers for their consistent high quality. You can rely on us to ensure reliable and consistent performance from your tools.

Extensive Product Portfolio

We offer a wide range of carbide rods in various sizes, characteristics, and properties. Moreover, we are committed to delivering prompt and dependable products for your customized carbide rod needs.

Application Range

- End Mills, Taps, Drills, punchs, etc.

Grade range to meet every need in the precision Solid Carbide End milling industry.

You can find the specific grade for any workpiece material or application.

Our solid carbide rods offer high performance and consistent quality.

Standard Tungsten Carbide Rods Size (mm)

| D | L |

| Φ1-56 | 310/330 |

PDF: Tungsten Carbide Rods Tolerances

Manufacturing process of cemented carbide rod: extrusion, forming, CIP cold isostatic pressing, HIP sintering, coreless grinding. Tungsten Carbide Round Stock

Ground carbide Rods with Chamfer–Inch/Metric(h5/h6/h7)

Has more uniform density, higher hardness and better toughness.

Ultra-fine, sub-fine and medium-grain cemented carbide.

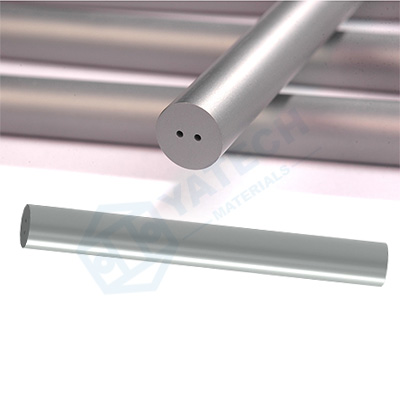

Rods with Central Coolant Hole.

Rods with Two Straight Coolant Holes.

with Coolant Holes.

Other Rods with Helical Coolant Holes.

Rods Blanks, Toolmaker Blanks, Cutting Tool Blanks, Tungsten carbide rod suppliers by China

Tungsten Carbide Rods Grades

We have successfully developed advanced carbide rod grades based on feedback from our customers.

These grades are specifically designed for the production of high-quality solid carbide cutting tools, including milling cutters, drills, taps, and punches for stamping dies.

We offer a wide range of carbide grades to meet the diverse needs of our customers.

| Grade | ISO Grade | Grain Size μm | Cobalt Content % | Hardness HRA | Density g/cm3 | TRS N/mm2 | Application |

|---|---|---|---|---|---|---|---|

| YU092 | К05-К10 | 0.2 | 9.0 | 94.00 | 14.44 | 4100 | Special ultra fine carbide grade for finishing high hardened materials (over HRC58), high light surface treatment of stainless steel, aluminium alloy and so on. |

| YU10UF | К05-К10 | 0.4 | 6.0 | 94.00 | 14.80 | 3800 | Suitable for highly hardened materials and finish machining of compost material; also used for PCB tools and gravers. |

| YU15UF | К10-К20 | 0.4 | 8.5 | 93.50 | 14.52 | 3800 | Suitable for machining hard materials, composites, РCB cutters and drills. |

| YU25UF | К20-К40 | 0.4 | 12.0 | 92.60 | 14.10 | 4200 | Suitable for milling stainless steel, non-ferrous metals, titanium alloys, high temperature alloys and high hardness materials (HRC50-58). |

| YU20F | К20-К40 | 0.6 | 10.0 | 92.30 | 14.37 | 4000 | Suitable for cutting alloy steel, stainless steel, non-ferrous metal, high temperature alloy and so on. |

| YU20 | К20-К40 | 0.7 | 10.0 | 91.90 | 14.40 | 3800 | Suitable for general milling and drilling applications, suitable for alloy steel, stainless steel, non-ferrous metal, high temperature alloy and so on. |

| YK05A | К15 | 1.0 | 6.0 | 92.50 | 14.90 | 2450 | Suitable for machining non-ferrous metals, high silica aluminium and graphite (diamond coated). |

Advantages of our tungsten carbide rods:

- Our tungsten carbide rods are made from 100% virgin tungsten carbide material, ensuring stable quality.

- We offer both unground (sintered blanks) and ground (h5, h6, h7) carbide rods to meet different requirements.

- Our carbide rods are available in various standard sizes and ISO grades, and we also offer customized grades.

- We provide customized service to ensure that we can meet your specific needs and provide satisfactory solutions.

- Our carbide rods offer higher cost performance compared to other options in the market, providing a competitive and better price.