Binderless Tungsten Carbide

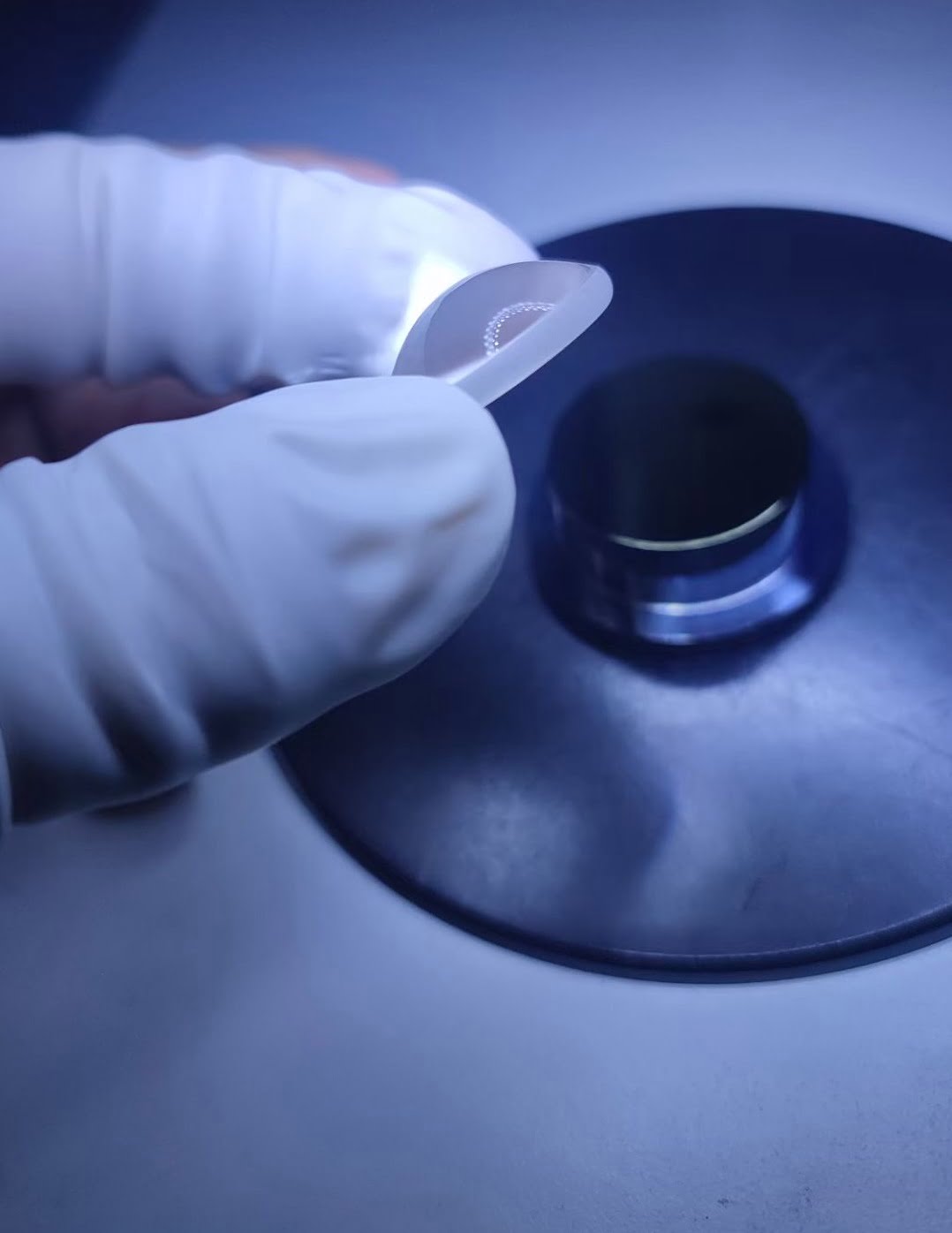

Aspherical glass mold, corrosion-resistant precision parts.

Optional grades of HIP sintering and SPS sintering technology.

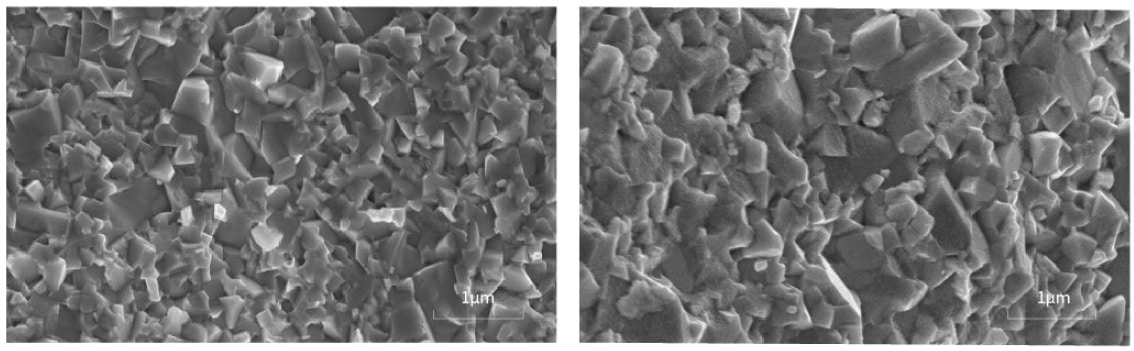

Made of nano-scale WC powder, better polishing performance.

High hardness, better wear resistance, High precision, high density, high elastic modulus, high corrosion resistance.

The content of the binder phase is extremely low. Compared with the traditional WC-Co cemented carbide, it has excellent super-mirror polishability. The polished surface roughness Ra can reach nanometer level, and its high hardness can ensure wear resistance and low thermal expansion. The coefficient is easy to control the dimensional accuracy of the product, especially suitable for high-precision optical glass lens molds.

We strive to create sustainable value for our customers around the world by meeting the most demanding needs of abrasion and corrosion resistance in a wide range of industrial applications. Please contact us to learn how our expertise can help you as well.

Blanks and Preforms, Nozzles, Optics Molds.

Nano-level surface finish

- Ultra-high density after UHT treatment, eliminates pores.

- Advanced process control to eliminate white spots and impurities.

- Ultra-fine raw material powder and excellent particle size distribution can effectively reduce Ry and Rz.

Low thermal expansion coefficient

- Excellent material ratio, effectively reducing the expansion coefficient.

- Stable quality control, effectively reducing thermal expansion fluctuations.

High hardness, high wear resistance, corrosion resistance, long life

- Ultra-high density and ultra-fine grains bring high hardness and good wear resistance.

- Very small amount of metal elements, no atomization at high temperature, corrosion resistance.

- Excellent DLC coating bonding force, bring longer service life.

Grade | Size(um) | g/cm³ | HV10 | T.R.S MPa | C.S MPa | T.C.E | HTC W/m.K | Poisson’s Ratio | ||

| 200℃ | 400℃ | 600℃ | ||||||||

| YC55 | 0.5-1.0 | 15.2 | 2700 | 1500 | 5600 | 4.0 | 4.4 | 4.7 | 53 | 0.19 |

| YC25 | 0.5-1.0 | 14.3 | 2400 | 2000 | 4500 | 4.0 | 4.8 | 5.1 | 48 | 0.20 |

Contact Us

We are always ready to provide you with binderless tungsten carbide solutions, optical mold manufacturing, material processing, coating recommendations, etc.