Matrices d'estampage Les outils d'emboutissage sont des outils utilisés dans le processus d'emboutissage pour façonner ou découper des feuilles de métal en formes ou en pièces spécifiques. Le processus d'emboutissage consiste à placer une feuille de métal entre deux matrices, puis à appliquer une pression sur la feuille de métal pour la déformer dans la forme souhaitée.

Le carbure cémenté est largement utilisé dans la fabrication de matrices d'estampage en raison de sa dureté élevée, de sa résistance à l'usure et de sa ténacité. Voici quelques-unes des façons dont le carbure cémenté est utilisé dans le matrice d'estampage industrie:

Poinçons et matrices :

Le poinçon et la matrice sont les deux principaux composants d'un matrice d'estampageLe poinçon est utilisé pour appliquer la force sur la tôle tandis que la matrice fournit la contre-force pour façonner la tôle. Le carbure cémenté est utilisé pour fabriquer le poinçon et la matrice en raison de sa grande résistance à l'usure, ce qui contribue à prolonger la durée de vie de l'outil.

Matrices de formage et de pliage :

Les matrices de formage et de pliage sont utilisées pour façonner des tôles en formes et angles complexes. Le carbure cémenté est utilisé pour fabriquer ces matrices en raison de sa dureté élevée, qui lui permet de résister aux forces extrêmes associées au processus de formage et de pliage.

Matrices progressives :

Les matrices progressives sont un type de matrice d'estampage qui peut effectuer plusieurs opérations sur une seule tôle, telles que le poinçonnage, le pliage et le formage. Le carbure cémenté est utilisé pour fabriquer les différents composants de la matrice progressive en raison de sa résistance à l'usure et de sa solidité élevées, ce qui lui permet d'effectuer plusieurs opérations sur une période de temps prolongée.

Matrices de découpage :

Les matrices de découpage sont utilisées pour découper des tôles en formes et tailles spécifiques. Le carbure cémenté est utilisé pour fabriquer les matrices de découpage en raison de sa dureté élevée, qui lui permet de conserver un tranchant tranchant pendant une période d'utilisation prolongée.

Le carbure joue un rôle essentiel dans la matrice d'estampage l'industrie en fournissant des outils de haute performance capables de résister aux forces extrêmes et à l'usure associées au processus d'emboutissage.

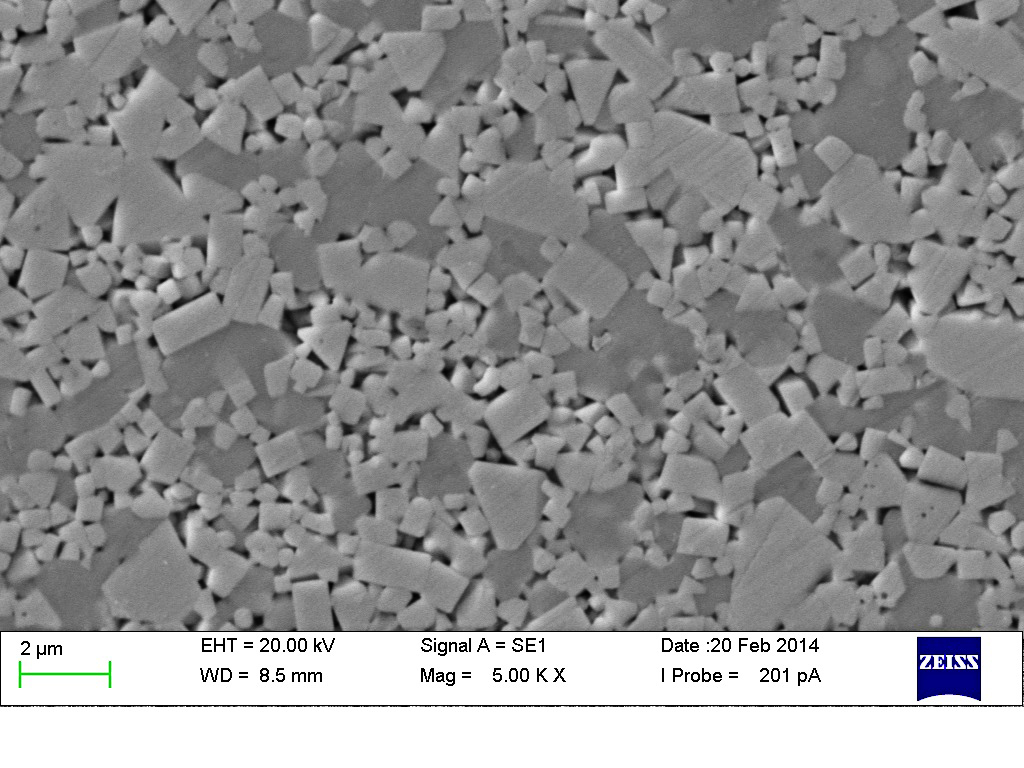

MEB en carbure de tungstène pour les matériaux Yatech

SEM en carbure de tungstène pour Yatech matériels