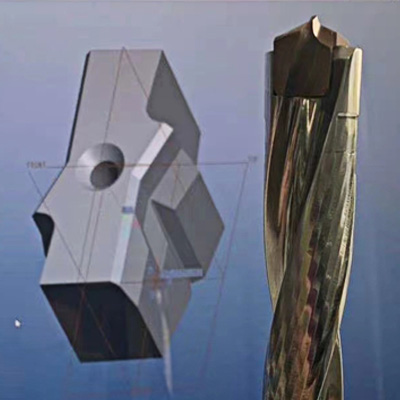

Indexable modular drills are one of the most advanced drilling tools used in the industry today. They are designed to make the process of drilling faster, more efficient, and more accurate than traditional drill bits. These drills are particularly useful for larger drilling applications where precision and accuracy are crucial. In this article, we will explore the advantages of indexable modular drills in terms of material, accuracy, efficiency, cost, and application.

Material Advantages

Indexable modular drills are made from high-quality materials such as carbide, which makes them durable and long-lasting. Carbide is a strong material that can withstand high temperatures and pressures. It also has excellent wear resistance properties, which means that the drill can maintain its sharpness for longer periods. This makes the drill more effective and efficient, especially when drilling through hard materials such as stainless steel or cast iron.

Accuracy Advantages

One of the significant advantages of indexable modular drills is their accuracy. These drills are designed to ensure that the hole drilled is of the correct diameter, depth, and location. The cutting edges of the drill are made with precision to create a clean, straight hole that is free from burrs and debris. This means that the drill can produce high-quality results consistently, which is essential in applications where accuracy is crucial.

Efficiency Advantages

Indexable modular drills are also designed to be highly efficient. They have a modular design that allows for easy replacement of worn-out parts. This means that only the damaged parts need to be replaced, reducing the downtime needed for maintenance. The drills also have a high drilling rate, which means that they can drill through materials quickly and efficiently. This can help to reduce the overall drilling time, leading to higher productivity.

Cost Advantages

Another advantage of indexable modular drills is their cost-effectiveness. While the initial investment in these drills may be higher than traditional drill bits, their long-term cost savings are significant. Due to their durability and efficiency, these drills have a longer lifespan than traditional drill bits. This means that they need to be replaced less often, reducing the cost of purchasing new tools. Additionally, the modular design of these drills means that only the worn-out parts need to be replaced, reducing the overall cost of maintenance.

Application Advantages

Indexable modular drills are versatile tools that can be used in a wide range of applications. They are particularly useful in applications where high precision and accuracy are essential, such as in the aerospace and automotive industries. These drills are also effective in drilling through hard materials such as stainless steel, cast iron, and titanium. They are also suitable for drilling large holes, making them ideal for applications where larger components need to be installed.

Conclusion

Indexable modular drills offer several advantages over traditional drill bits, including material, accuracy, efficiency, cost, and application. These drills are made from high-quality materials such as carbide, which makes them durable and long-lasting. They are designed to be highly accurate and efficient, making them ideal for applications where precision and speed are essential. Additionally, their modular design means that they are cost-effective and versatile, making them suitable for a wide range of applications. Overall, indexable modular drills are an excellent investment for businesses looking to improve their drilling processes and increase productivity.

As provider of indexable modular drills and related tools, we offer our customers a complete range of drill press tools to meet their drilling and milling needs. Our flexibility in supplying both rough and fine ground products means that customers can choose the best option for their specific requirements. In addition, our fast delivery times and rigorous quality control processes ensure that our customers receive high-quality products on time.

At Yatech Materials, we have many years of experience in the production of shaped tools, including indexable modular drills. This expertise allows us to provide expert advice and innovative solutions to our customers. Our commitment to consistent quality ensures that our tools perform accurately and efficiently, resulting in a more effective manufacturing process.

In summary, at Yatech Materials, we pride ourselves on providing a complete range of high-quality drill press tools, including indexable modular drills. Our fast delivery times, consistent quality, and many years of experience in the industry make us a trusted and reliable partner for businesses looking to improve their drilling and milling processes.