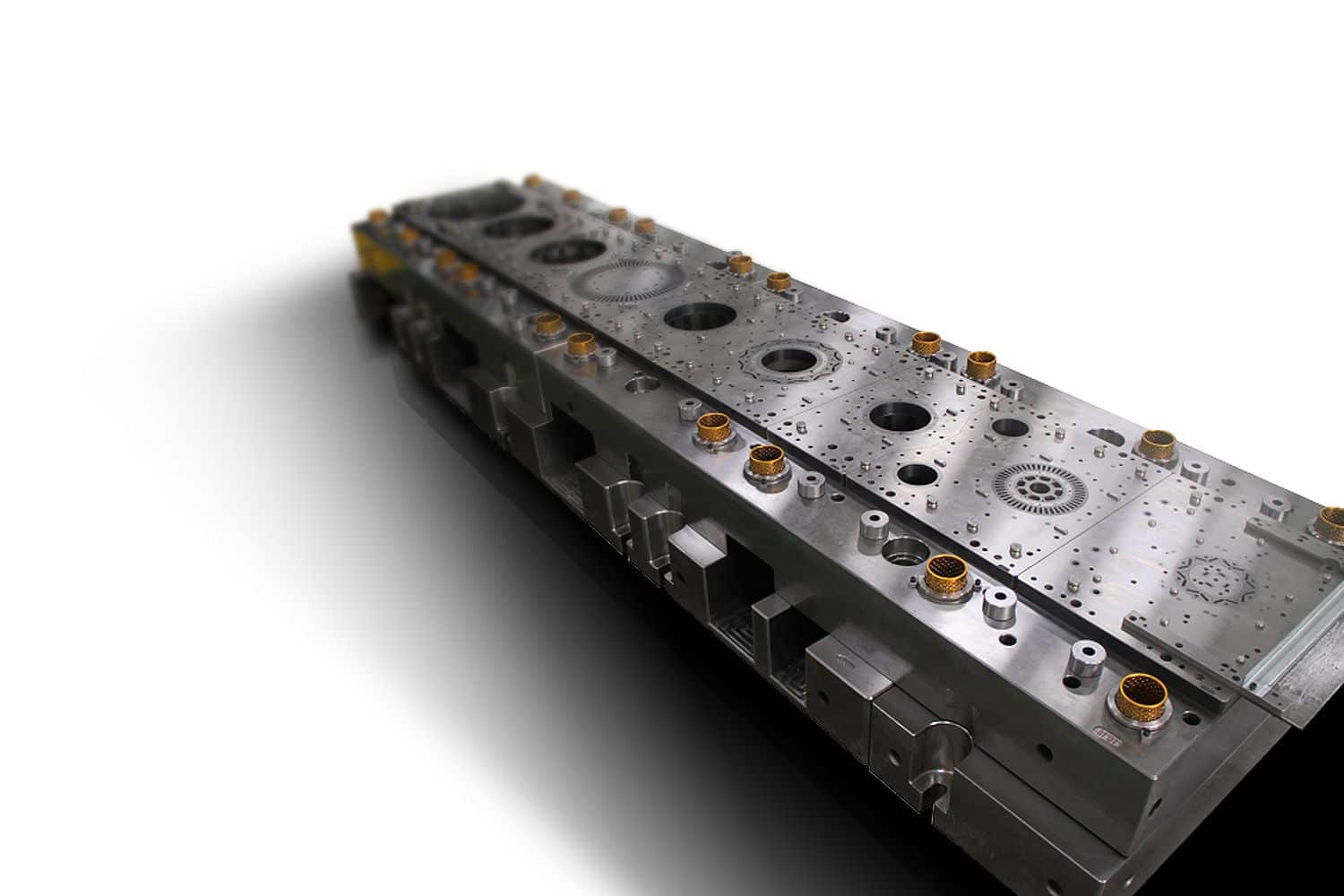

Stamping dies are essential tools in manufacturing processes that are used to form and shape metal sheets into various components. One of the key components of stamping dies are carbide EDM (Electrical Discharge Machining) blocks. These blocks are made from tungsten carbide, which is an extremely hard and durable material that is able to withstand the high pressures and forces generated during the stamping process.

Here are some ways in which carbide EDM blocks can improve your stamping die performance:

Wear Resistance: Carbide EDM blocks are highly resistant to wear and tear, which means they can withstand the constant rubbing and grinding of metal sheets during the stamping process. This helps to extend the life of your stamping die and reduce maintenance costs.

Dimensional Stability: Carbide EDM blocks have high dimensional stability, meaning that they are able to maintain their shape and size over time, even under extreme pressure and temperature conditions. This helps to ensure consistent and accurate stamping results, which is critical in precision manufacturing processes.

High Thermal Conductivity: Carbide EDM blocks have high thermal conductivity, which means that they are able to dissipate heat quickly and efficiently. This is important because excessive heat can cause deformation and warping in the stamping die, which can result in defective components and increased scrap rates.

Corrosion Resistance: Carbide EDM blocks are highly resistant to corrosion, which helps to protect your stamping die from damage caused by exposure to moisture, chemicals, and other corrosive substances.

Carbide EDM blocks can provide significant benefits to stamping die performance, including increased wear resistance, dimensional stability, thermal conductivity, and corrosion resistance. This can help to improve manufacturing efficiency, reduce costs, and enhance product quality.