When it comes to high-speed stamping of stainless steel sheets, there can be several difficulties. Stainless steel is a tough and hard material that can cause rapid wear and tear of the stamping dies. This can lead to frequent tool changes, increased downtime, and decreased productivity. However, stamping dies made of cemented carbide can help overcome these difficulties.

Advantages of Stamping Stainless Steel with Cemented Carbide Dies:

- High wear resistance: Cemented carbide is known for its exceptional hardness and wear resistance, making it an ideal material for stamping tough materials like stainless steel.

- Good toughness: Cemented carbide also has good toughness, which allows it to withstand the high pressures and forces that occur during high-speed stamping operations.

- Excellent thermal conductivity: Cemented carbide has high thermal conductivity, which helps to dissipate heat generated during the stamping process, reducing the risk of damage to the dies or workpiece.

- Superior surface finish: Due to its high wear resistance, cemented carbide can maintain a smooth surface finish over time, reducing the need for frequent polishing and maintenance.

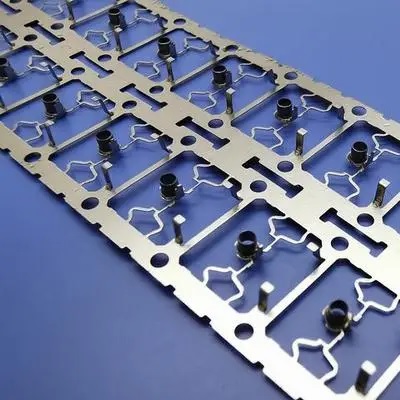

Parts of Cemented Carbide Mainly Used in High-Speed Stamping Dies:

- Carbide inserts: These are small pieces of cemented carbide that can be used to reinforce the cutting edge of the stamping dies, allowing for faster and more efficient stamping operations.

- Punches and dies: These are larger pieces of cemented carbide that can be used to form and cut the workpiece during the stamping process. Cemented carbide punches and dies can withstand the high pressures and forces of high-speed stamping operations.

- Usually we take carbide EDM blocks (plates) and use electrical discharge machining and diamond wheel grinding machining to make these parts.

Precautions for Making High-Speed Stamping Dies with Cemented Carbide:

- Design: Proper design of the stamping dies is crucial to ensure that they can withstand the high pressures and forces of the stamping process. This includes choosing the right shape and size for the dies, as well as ensuring that the carbide inserts are properly secured.

- Manufacturing: Precision manufacturing techniques are necessary to ensure that the stamping dies are made to the correct tolerances and specifications. This includes using high-quality carbide materials and ensuring that the dies are properly heat-treated and finished.

- Coating: Adding a coating, such as a diamond-like carbon (DLC) coating, to the stamping dies can further improve their wear resistance and durability.

In conclusion, cemented carbide can be an effective solution for high-speed stamping of stainless steel sheets. By using carbide inserts and dies, stamping operations can be made more efficient, with fewer tool changes and less downtime. However, it’s important to consider the specific application and requirements before choosing this material, and to ensure proper design and manufacturing techniques are used to create durable and effective stamping dies.