Screw Superiority: The Advantages of Carbide Cold Heading Dies for Fastener Manufacturing

How Carbide Dies Outperform Steel Dies in Quality, Durability and Cost-Efficiency

Cold heading, also known as cold forming, is a technique used for rapidly forming metal parts such as screws, bolts and many other fasteners. It involves striking a cold metal slug with a heavy force to shape it into the desired form inside a die. The force of the strike exceeds the metal’s yield strength, causing the metal to flow into the shape of the die cavity.

1.Cold heading is a popular method for fastener manufacturing because it offers several advantages over other methods such as machining or hot forging. Some of these advantages are:

Higher production speed and efficiency

Less material waste and scrap

Better surface finish and dimensional accuracy

Improved mechanical properties and strength

Lower energy consumption and environmental impact

However, cold heading also poses some challenges for the die material. The die has to withstand high pressure, impact, abrasion, heat and corrosion from the metal slug. The die also has to maintain its shape and size after repeated strikes without cracking or deforming. Therefore, the choice of die material is crucial for the quality and performance of the cold headed parts.

2.Traditionally, steel has been used as the die material for cold heading. However, steel dies have some limitations and disadvantages that affect their performance and durability. Some of these are:

Low hardness and wear resistance

High tendency to deform and crack under stress

Frequent need for replacement and maintenance

High cost of production and operation

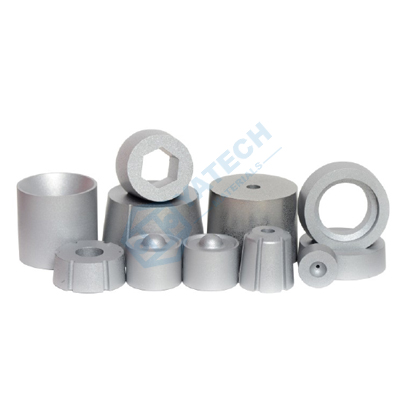

3.To overcome these limitations, carbide dies have emerged as a superior alternative for cold heading. Carbide dies are made of tungsten carbide (WC), a hard and dense material that is pressed and sintered by powder metallurgy. Carbide dies have several advantages over steel dies that make them more suitable for cold heading applications. Some of these are:

High hardness and wear resistance

High bending strength and fracture toughness

High fatigue strength and impact resistance

Low tendency to deform and crack under stress

Long service life and less need for replacement and maintenance

Low cost of production and operation

Carbide dies can be used as the core insert to be pressed in a steel jacket, or as the whole die body. Carbide dies can also be coated with various materials such as titanium nitride (TiN), titanium carbonitride (TiCN), titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC) to enhance their performance and durability. Carbide dies can be customized to fit different shapes and sizes of fasteners according to customer requirements.

According to some studies, carbide dies can produce up to 10 times more parts than steel dies before needing replacement1. This means that carbide dies can save time, money and resources for fastener manufacturers by reducing downtime, labor and tooling costs. Carbide dies can also improve the quality and consistency of the cold headed parts by reducing defects, variations and rejections.

In conclusion, carbide dies are a superior choice for cold heading fasteners because they offer higher quality, durability and cost-efficiency than steel dies. Carbide dies can help fastener manufacturers achieve better productivity, profitability and competitiveness in the market. Therefore, carbide dies are the future of fastener manufacturing.