Replacing steel with cemented carbide can offer several advantages such as increased wear resistance, toughness, and durability. However, there are some precautions that should be taken when replacing steel with cemented carbide:

Material Selection:

Cemented carbide is a composite material that consists of tungsten carbide grains held together by a metallic binder such as cobalt. The material should be selected based on the specific application requirements, taking into consideration factors such as wear resistance, toughness, and corrosion resistance.

Component Design:

The design of the component should be optimized for the properties of cemented carbide. For example, cemented carbide is more brittle than steel, so component designs should avoid sharp corners or edges that could create stress concentrations and cause the component to fracture.

Manufacturing Process:

Cemented carbide requires specialized manufacturing processes such as powder metallurgy, sintering, and grinding. It is important to use proper manufacturing techniques and equipment to ensure that the finished product meets the required specifications.

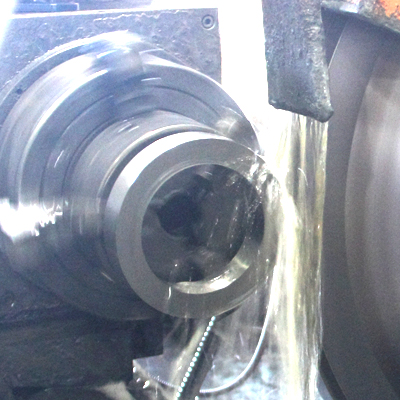

Machining:

Cemented carbide is much harder and more brittle than steel, which can make it more challenging to machine. Specialized cutting tools and machining techniques are required to achieve the desired shape and dimensions while maintaining the integrity of the material.

Coating(This is not necessary):

Cemented carbide can be susceptible to chemical attack and oxidation, which can affect its performance over time. Coatings can be applied to improve corrosion resistance and extend the life of the component.

Safety Precautions: Cemented carbide is a hard and brittle material that can pose a hazard if not handled properly. Appropriate safety precautions, such as using protective gear and proper handling techniques, should be taken to prevent injury.

Overall, replacing steel with cemented carbide can offer significant advantages in terms of performance and durability. However, it is important to carefully consider the specific requirements of the application and take appropriate precautions during material selection, design, manufacturing, machining, coating, and handling.