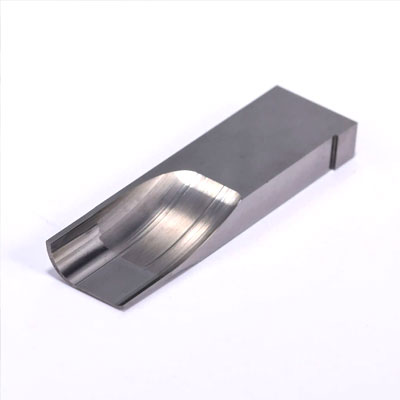

Tungsten carbide is a popular material used in manufacturing for its excellent hardness, wear resistance, and strength. However, machining this material can be challenging due to its high hardness and brittleness. In this article, we will discuss the various methods of machining tungsten carbide, their considerations, advantages, and disadvantages.

Methods of Machining Tungsten Carbide

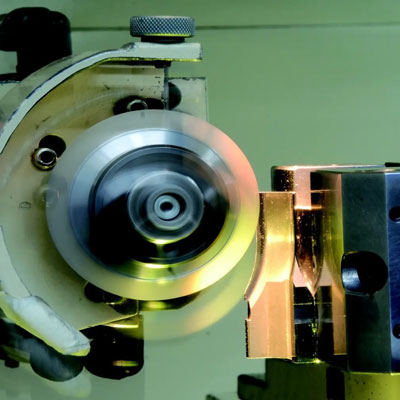

- Grinding: Grinding is the most common method of machining tungsten carbide. It involves the use of a grinding wheel to remove material from the workpiece. The grinding wheel is made of abrasive particles bonded together with a binder material. Diamond or cubic boron nitride (CBN) abrasive grains are commonly used for grinding tungsten carbide.

- EDM (Electrical Discharge Machining): EDM is a non-traditional method of machining that uses electrical energy to remove material from the workpiece. In EDM, a conductive tool and a workpiece are submerged in a dielectric fluid. An electrical discharge is then used to remove material from the workpiece. EDM is often used for complex shapes and profiles.

- Laser Cutting: Laser cutting uses a high-energy laser beam to cut and shape tungsten carbide. The laser beam melts the material, and a high-pressure gas jet blows the molten material away from the workpiece. Laser cutting is suitable for thin sections and intricate shapes.

Considerations for Machining Tungsten Carbide

- Tool Selection: The choice of the tool material is crucial for machining tungsten carbide. Diamond or CBN tools are commonly used for grinding, while tungsten carbide or copper-tungsten tools are used for EDM.

- Workpiece Fixturing: Due to the brittleness of tungsten carbide, proper workpiece fixturing is essential to prevent cracking or chipping during machining.

- Machining Parameters: Machining parameters such as cutting speed, feed rate, and depth of cut should be carefully selected to avoid excessive tool wear or damage to the workpiece.

Advantages and Disadvantages of Each Method of Machining

- Grinding: Grinding is the most common and cost-effective method of machining tungsten carbide. It provides a high-quality finish and can be used for both rough and finish grinding. However, grinding can be time-consuming, and the tool life can be limited.

- EDM: EDM is suitable for machining complex shapes and profiles in tungsten carbide. It does not produce heat or mechanical stress, making it ideal for fragile parts. However, EDM can be slower than other methods and may produce a rougher surface finish.

- Laser Cutting: Laser cutting is fast and precise and can produce intricate shapes in tungsten carbide. It does not produce mechanical stress, and there is minimal tool wear. However, laser cutting can be expensive and is limited to thin sections.

Conclusion

Machining tungsten carbide requires careful consideration of tool selection, workpiece fixturing, and machining parameters. Grinding is the most common and cost-effective method of machining tungsten carbide, while EDM and laser cutting are suitable for complex shapes and thin sections. Each method has its advantages and disadvantages, and the choice of method will depend on the specific requirements of the application. With the proper machining techniques and equipment, tungsten carbide can be machined to produce high-quality parts with excellent wear resistance and strength.