Background:

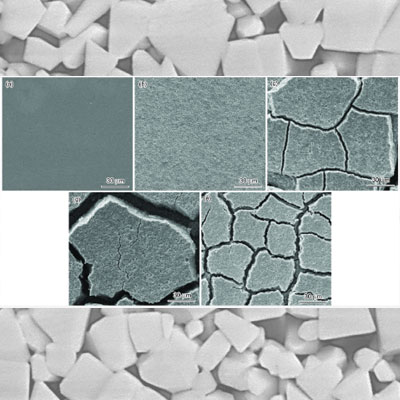

A steel manufacturing company operates large rolling mill equipment to process molten metal into various shapes and sizes of metal plates, bars, and other products. Due to the high requirements for the rolling mill’s rolls, the company decides to use Tungsten carbide roll rings as wear-resistant parts for the rolling mill.

Objective:

By using carbide roll rings, the goal is to improve the wear resistance and operational efficiency of the rolling mill, extend the service life of the roll rings, reduce maintenance costs, and ensure product quality.

Carbide rolls Solution:

Applying Carbide roll rings to the steel mill rolling mill provides the following advantages:

- Wear resistance: Carbide roll rings are made of high-hardness materials such as tungsten titanium carbide, offering excellent wear resistance to withstand high temperatures and pressures, thereby maintaining a longer service life.

- Excellent thermal stability: Tungsten carbide roll rings can maintain stable performance in high-temperature environments, ensuring the reliability of the rolling mill during prolonged operation.

- Reduced downtime: The long service life and wear resistance of hard alloy roll rings reduce the frequency of replacement and maintenance, resulting in reduced downtime of the rolling mill and improved production efficiency.

Carbide rolls Data Match:

Based on actual data, the application of carbide roll rings in steel mill rolling mills demonstrates significant effectiveness:

- 30% extension in roll ring service life: Compared to traditional roll ring materials, the wear resistance of carbide roll rings allows them to withstand higher pressures and friction for a longer period, extending the service life of the roll rings.

- 20% reduction in maintenance costs: The longer service life and reduced maintenance frequency lead to lower maintenance costs, including decreased production downtime and parts replacement expenses.

- Improved product quality: The stability and wear resistance of Carbide roll rings ensure uniform and stable rolling pressure, thereby enhancing product quality and surface finish.

By adopting Carbide roll rings, the steel mill achieves notable benefits in the rolling mill equipment, including extended roll ring service life, reduced maintenance costs, and improved product quality. This use case demonstrates the reliability and advantages of Carbide roll rings in steel mill rolling mills.