What are tungsten carbide wear parts?

It is tungsten carbide and cobalt, nickel and other metals made of cemented carbide. which has extremely high wear resistance and 8-10 times the life of ordinary steel.

It is divided into cobalt based carbide and nickel based carbide. Usually cobalt based carbide is used, in food industry we have to use nickel based carbide because cobalt is harmful to human body.

Advantages of our carbide manufacturing

At Yatech Materials we specialise in the customisation of carbide wear parts and tungsten carbide blanks with complex geometries.

Our products are suitable for almost all types of mechanical wear applications and offer excellent corrosion resistance, high temperature resistance and high pressure capabilities. By replacing high speed steel, high manganese steel and other metals with tungsten carbide through reasonable design, we can help you greatly improve the service life of your products.

Solutions for wear-resistant carbide parts

Our team of experts is dedicated to providing reliable solutions for the parts you need, ensuring maximum performance and durability. Whether you need wear parts for oil and gas extraction and handling equipment, stamping dies and tools, food processing machinery, plastic extrusion machinery, agricultural machinery, tungsten carbide roof tile tools or any other industry, we have you covered.

We also use high quality tungsten as a counterweight material for fishing counterweights, pinewood derby counterweights and other applications, providing excellent balance and stability.

*Wear is the damaging, gradual removal or deformation of material at solid surfaces.

Oil Field Wear Parts

Powder Metallurgy Forming Die

Tungsten carbide Powder compacting molds for producing automobile parts, ceramic electrical parts, magnets, medical drugs, etc. High hardness, wear resistance, high efficiency.

Powder metallurgy sizing-dies

Powder metallurgy complicated and special dies

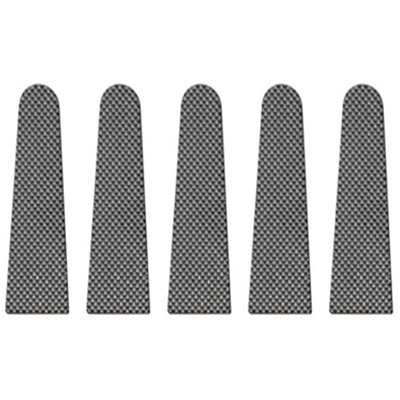

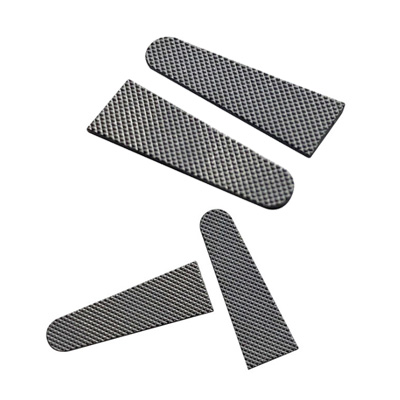

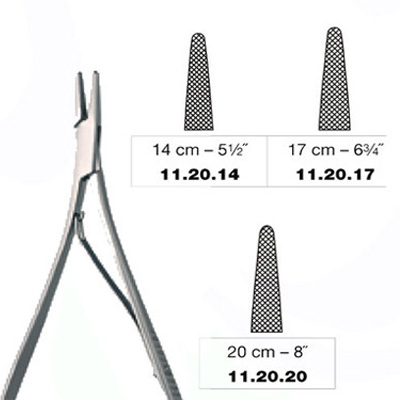

Carbide for Needle Holder,Carbide for Medical

Blank needle holder tips, Ground needle holder tips

The Blank of the needle holder tip is delivered in a sintered or ground state.

Standard products and customized products.

It can be manufactured according to customer’s product design drawings and surface roughness.

Multi-grade selection, higher wear resistance, corrosion resistance.

Improve efficiency and reduce costs.

Customized Carbide

Screw drilling tools, centralizers, diverters, fracturing and other tungsten carbide cobalt nickel parts.

Customized carbide parts for the oil extraction and transportation industry, even complex geometries are manufactured through advanced forming techniques.

Carbide parts, better wear resistance, better corrosion resistance

Large size cemented carbide

Ring D820*d710* H120mm

Rod D150*L900mm

Strip L1200*W30*H10mm

Whether you need wear parts for mining, drilling, cutting or any other industrial application, we have you covered. Our products are tested to ensure optimum performance and we pride ourselves on providing exceptional customer service.

We also offer competitive pricing and fast delivery so you can get the parts you need quickly and affordably. Choose Yatech Materials for the best tungsten carbide wear parts on the market.