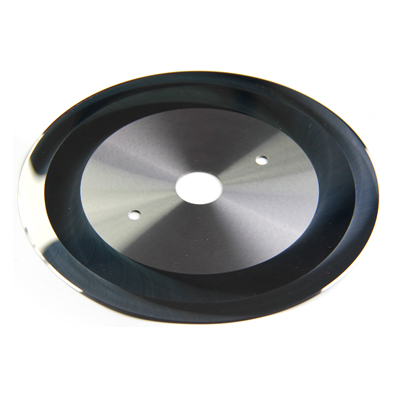

Tungsten Carbide Slitter Blades / Slitting Knives

What is tungsten carbide slitter blade / Slitting Knives ?

Essentially, it is a slitting blade made using tungsten carbide manufacturing.

Tungsten Carbide is an exceptionally durable and tough material, featuring high hardness, wear resistance, flexural strength, and corrosion resistance. A special polishing process is employed to mirror-polish the cutting edge, which helps to minimize friction between the tool and the processed product. It is an essential tool for slitting machines.

Tungsten Carbide slitter blade grade selection

Due to the diverse materials that require slitting, we have formulated a range of carbide grades that are suited to specific material types and applications.

Please refer to the table displayed below for more information.

| Grade | Grain Size μm | Co% | Density g/cm³ | Hardness HRA | T.R.S N/m m² | Application |

|---|---|---|---|---|---|---|

| YA25UF | Super fine | 12 | 14.00-14.20 | 92.4-93.0 | 3500 | Corrugated board, Cardboard, Leather, Composite materials |

| YA30K | Sub-fine | 15 | 14.00-14.10 | 88.5-89.0 | 3200 | Nonferrous metals |

| YA05U | Sub-fine | 6 | 14.75-15.00 | 92.8-93.2 | 2500 | Cardboard, Optical fiber, Lather |

| YA10U | Sub-fine | 8 | 14.60-14.80 | 92.0-92.5 | 2500 | Composite materials |

| YA30U | Sub-fine | 15 | 13.85-14.00 | 89,7-90.2 | 3200 | Cardboard |

| YA20U | Sub-fine | 10 | 14.35-14.50 | 91.4-91.8 | 3200 | Cardboard, Chemical fiber , Optical fiber, Lather |

| YA26U | Sub-fine | 13 | 14.00-14.10 | 90.4-90.8 | 3500 | Corrugated board, Battery pole pieces |

| YA35M | Fine | 18 | 13.75-13.85 | 86.0-86.5 | 3200 | Sheet metal |

| YA25K | Fine | 12 | 14.20-14.40 | 89.5-90.0 | 3300 | Plastics, Paper |

| YA05M | Medium | 6 | 14.90-15.00 | 90.9-91.3 | 2400 | Film |

| YA15M | Medium | 9 | 14.55-14.70 | 89.7-90.2 | 2800 | Asbwtos |

| YA25M | Medium | 12 | 14.20-14,40 | 88.5-89.0 | 3000 | Plastics |

| YA30M | Medium | 15 | 14.00-14.10 | 87.2-87.6 | 3000 | Paper, Nonferrous metals |

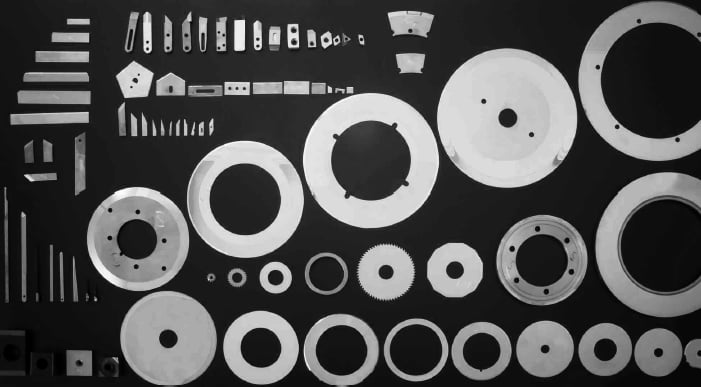

Tungsten Carbide slitter blade dimensions (reference)

OD20-340*ID 3-280*T 1.6-30mm

Tolerances of carbide slitting blades (reference)

OD(mm) | ID(mm) | T (mm) | Flatness (mm) | Surface Roughness | Concentricit |

|---|---|---|---|---|---|

| +0.2/-0.2 | +0.01/+0.03 | +0.001/-0.002 | 0.005 | Ra0.1-0.2μm | 0.05 |

Application of Tungsten Carbide Slitter Circular Blade

Main application industries: lithium battery pole piece, magnetic tape, adhesive tape products, film, rubber, copper foil, aluminum foil, non-manufacturing cloth, composite packaging materials, cigarettes and other high-precision slitting industry.

Tungsten carbide slitting blade has a wide range of applications and can be used in many fields such as pharmaceuticals, food, electronics, communications, home appliances and so on.

Slitter blade made of Tungsten Carbide can not only improve the production efficiency, but also improve the quality of products. Therefore, it is a very important industrial cutting equipment, widely used in various fields.

#Metal Foil Slitter Blade #Lithium Battery Pole Blade Slitter Blade #Corrugated Precision Slitter Blade #Carrier Tape Slitter Blade

Analysis Of Typical

Problems Of Corrugated Board Slitting Blade

A. The hardness of the blade and corrugated board might not match.

A. Unstable swing grinding wheels may cause this problem, even break the blades.

B. A collision with hard objects may cause the chips on the cutting edge.

A. incorrect assembly e.g. deformed flange plate; wrong screwing will cause the breakage of blades.

B. Unstable swing grinding wheels break the blades; please check the bearing of the grinding wheels.

C. The problem may be caused by collision with other hard objects.

A. Please check the cutting edge of your blade. Is the cutting-edge sharp enough?

B. The corrugated board is too wet.

A. Is the grain size of the grinding wheel adequate?

Too coarse a grain size of grinding wheel shortens the lifespan/performance time of blades.

B. Excessive grinding: the grinding interval is too short or the grinding pressure is too high.

Contact us

We are always ready to provide you with questions about carbide cutting tools, grades, materials, performance, how to buy, etc.