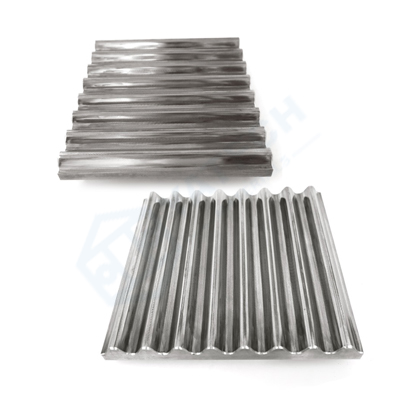

Carbide Jaw Plate, Wear Plate

It is used in the jaw crusher, where it is divided into a fixed and movable plate. This plate is an important wear-resistant component of the jaw crusher.

It exhibits a wear resistance that is 8 to 10 times more than chrome steel and manganese steel. Its primary function is to crush raw materials such as ore and polysilicon.

The carbide jaw plate (wear plater)has a significantly longer lifespan than competing materials, requiring minimal maintenance. This helps maintain the raw material’s purity at a high level.

About Carbide Grade

The operation of the jaw crusher plant produces a significant amount of impact. As a result, we have developed hard carbide grades with better impact resistance.

These grades are composed of medium and coarse-grained tungsten carbide double-grain material with a cobalt content ranging from 15% to 20%. This grade design offers both wear and impact resistance to the tungsten carbide.