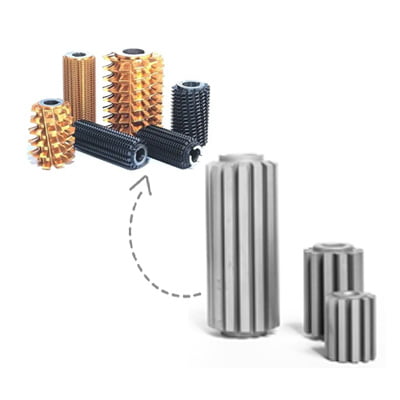

Tungsten Carbide Gear Cutting Tool Blanks

We manufacture to custom dimensions according to the agreed solution.

Other carbide grades and designs are tailored to each customer’s individual needs and requirements.

Advantages of carbide gear cutting tool blanks

Our carbide blanks have longer tool life, typically 10-40 times longer than HSS. Carbide hobbing tools can effectively improve the finish of the product being machined.

We use ultra-fine grades of carbide, resulting in gear hobs with excellent performance in cutting easy-to-cut materials. Net-near-molded carbide preform technology improves efficiency, reduces your grinding allowance and ensures the cutting accuracy of your gear hobs.

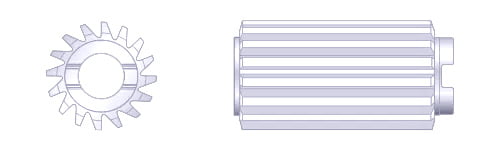

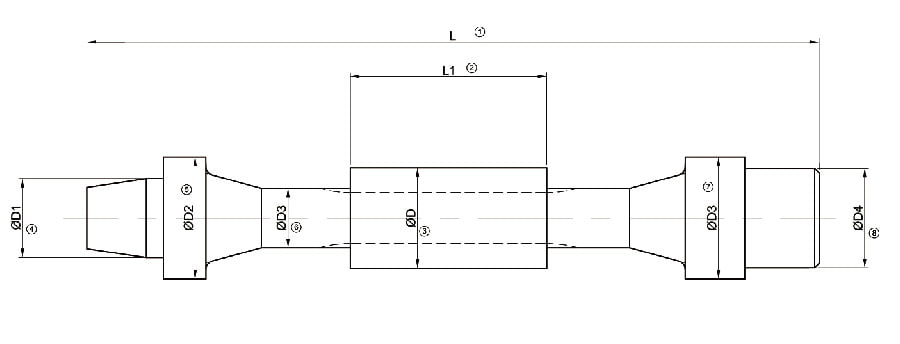

Carbide Hob blanks

Bore-type hobs with gashes

Shank-type hobs with gashes

gears, gearboxes and a wide range of small to medium module external gears. Rough grinding is offered to produce close to finished formed geometries, reducing your grinding allowance and increasing efficiency and reducing costs.

We can manufacture to customer specifications.

Our carbide hob blanks offer longer tool life, better edge retention and higher productivity.

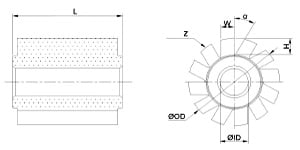

Size unit: mm

| OD | ID | L | H | W | α | z |

| 25.8 | 9.6 | 20-80 | 4.1 | 3.3 | 35 | 12 |

| 32.8 | 12.6 | 20-80 | 5.3 | 4.2 | 35 | 12 |

| 40.8 | 15.6 | 20-100 | 7.3 | 5 | 35 | 12 |

| 40.8 | 15.6 | 20-100 | 7 | 5.2 | 30 | 12 |

| 50.8 | 15.6 | 20-180 | 7.9 | 7.8 | 30 | 12 |

| 50.8 | 21.6 | 20-180 | 8.6 | 6.5 | 35 | 12 |

| 50.8 | 21.6 | 20-180 | 7.6 | 5.3 | 30 | 15 |

| 60.8 | 21.6 | 20-180 | 11 | 7.6 | 35 | 12 |

| 60.8 | 21.6 | 20-180 | 10 | 7.9 | 30 | 12 |

| 70.8 | 31.2 | 20-180 | 11.9 | 7.9 | 40 | 12 |

| 70.8 | 31.6 | 20-180 | 9.3 | 5.9 | 35 | 16 |

| 80.8 | 31.4 | 20-180 | 8.5 | 9.5 | 30 | 14 |

| 80.8 | 31.4 | 20-180 | 12 | 8.2 | 30 | 15 |

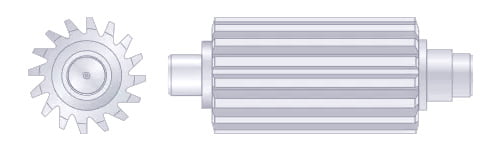

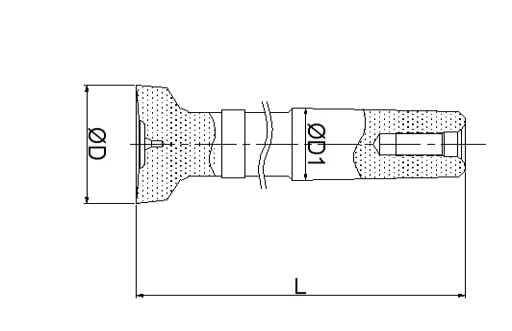

Shank Type Hob

We manufacture tungsten carbide Grooved or ungrooved shank type hobs are available.

| D | ID | L |

|---|---|---|

| 16-85 | * | 180-330 |

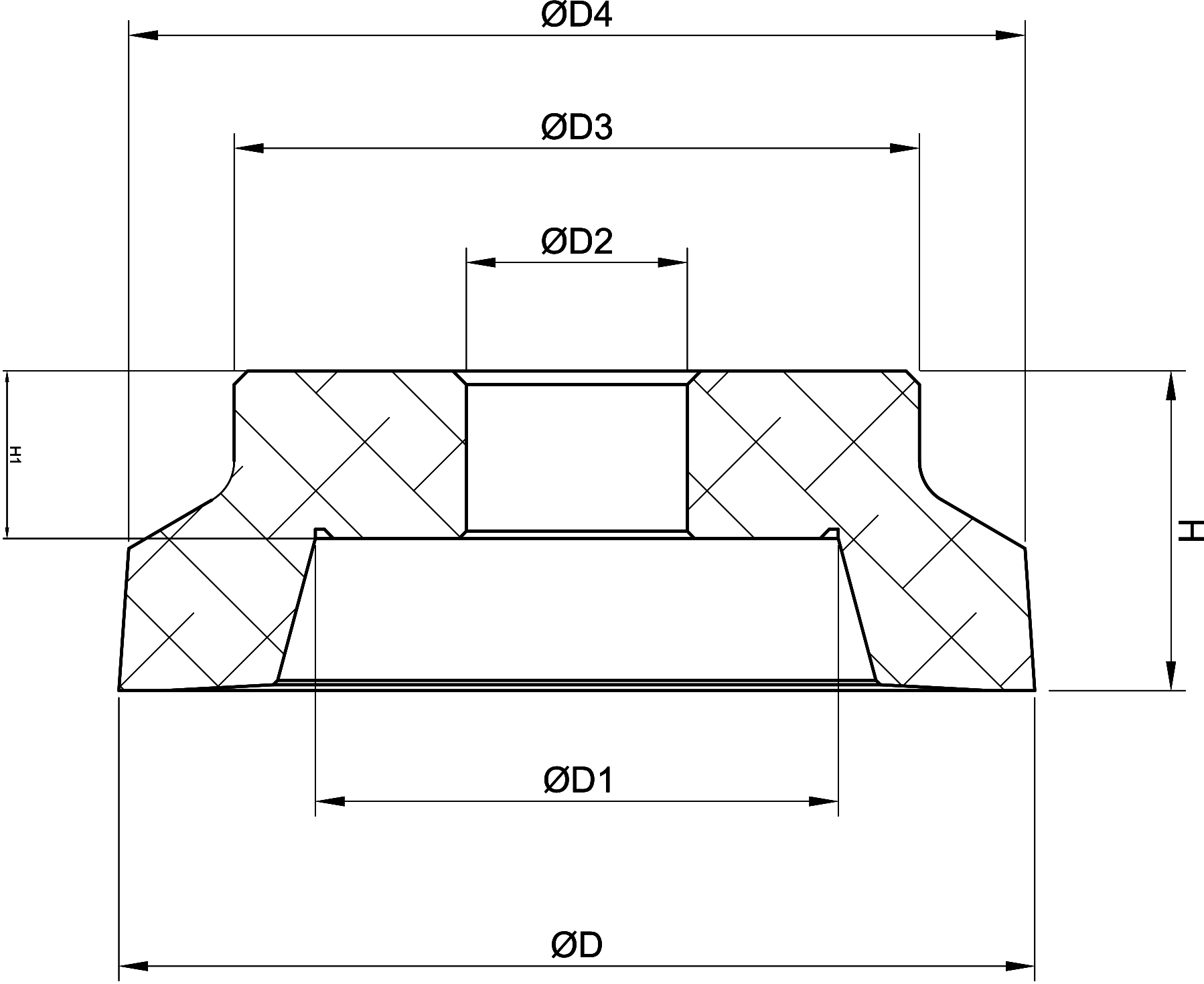

Bowl Shaper Cutter

Power Skiving Blanks

Specialized tools for the production of internal and external gears. They are particularly effective for machining internal gears. Combining the principles of gear hobbing and gear shaping, they enable the machining of high precision gears, splines and other complex tooth forms.

Gear cutting blanks are designed to fit into any CNC machine tool holder, resulting in low investment costs. The cutting edge corresponds to the tooth shape required for the particular gear or spline being produced. Carbide can withstand the high cutting forces of the power planing process, has a longer life and can be resharpened multiple times to produce more parts.

The process of preforming gear cutting blanks with cemented carbide improves the productivity of gear cutting tool manufacturing. This process improves quality at a lower cost and is an inexpensive, fast and effective alternative to traditional gear cutting methods.

Solid carbide arbor mount

Size unit: mm

| OD | ID | H |

|---|---|---|

| 45-165 | 25-65 | 15-45 |

Solid carbide shank style

Size unit: mm

| OD | ID | H |

|---|---|---|

| 6-55 | * | 50-200 |

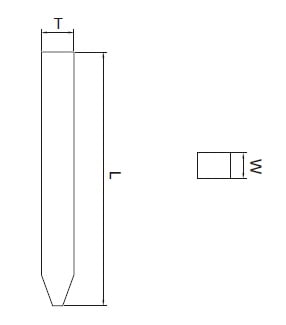

Bevel Stick Blade Blanks

Size unit: mm

| L | T | W |

|---|---|---|

| 104.75 | 13.21 | 10.67 |

| 106 | 13.21 | 10.67 |

| 108 | 14.73 | 21.59 |

Carbide Gear Hob Blank Grades

| Grade | Co% | Hardness (HRA) | Density (g/cm3) | TRS (Mpa) |

| YU20 | 10.3 | 91.5 | 14.4 | ≥3500 |

| YU25UF | 12.0 | 92.6 | 14.1 | ≥4200 |

| YU092 | 9.0 | 93.6 | 14.4 | ≥4100 |