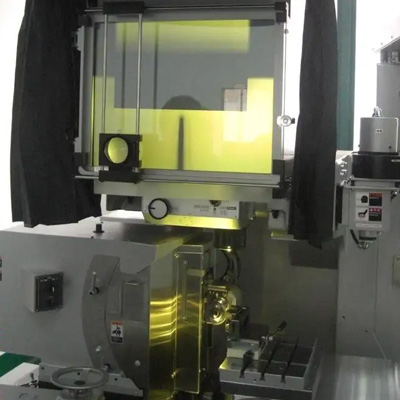

PG (Profile Grinder) is a popular precision grinding method. It is mainly used for processing key parts in precision equipment such as high-speed precision stamping progressive dies. It is suitable for grinding carbide parts with high hardness (HRA) of 88-96. shape grinding.

According to the size of the workpiece, it is enlarged by 20-50 times through the projector and projected on the screen before grinding, and the tolerance can be guaranteed to be within 0.001mm.

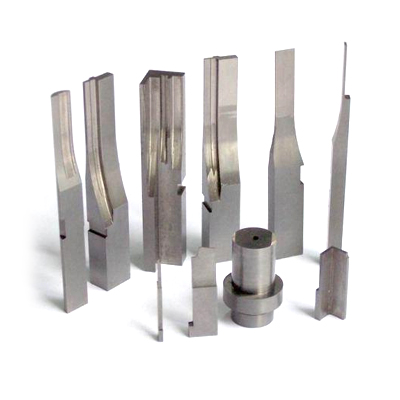

General processing of connector stamping progressive die carbide cutting edge and punch, terminal, precision half-stroke punch, lower die into the block and stripper into the sub and other stamping die parts.

With the improvement of precision requirements for precision stamping die parts processing, PG grinding processing shows its charm.

1. The precision of PG grinding carbide can reach 1μm;

2. In the R angle precision control, it can reach 0.001mm;

3. Carbide surface has better finish, surface roughness: RZ~~0.2μm / F1.0mm/min. The product that is ground and processed with PG looks like a mirror on the side, and the front is also very smooth, and the processing produces very small lines;

4. The products produced by PG grinding have high durability and long life due to their high precision.

Before the PG grinding process, the grinding machine will first perform rough machining, and then use PG for finishing. Grinders and PGs are inseparable from each other.

In the precision stamping progressive die, PG is mainly used for the manufacture of high-precision die carbide punches, dies, inserts, etc. for relays, continuous terminal dies, metal stamping parts, LEDs and high-speed continuous stamping dies.

The main reasons why our customers choose to use PG grinding are mainly due to the high requirements of precision stamping and progressive die precision carbide parts, the product has R angle, and has strict finish requirements.