Content on Tungsten Carbide Welding

1. Issues Encountered During Tungsten Carbide Brazing

The brazability of tungsten carbide is relatively poor. This is due to its high carbon content, with uncleaned surfaces often containing free carbon, which hinders the wetting of the filler metal. Additionally, tungsten carbide tends to oxidize at brazing temperatures, forming an oxide layer that further affects the wetting characteristics of the filler metal. Therefore, pre-brazing surface cleaning is crucial for enhancing the wettability of the filler metal on tungsten carbide. When necessary, coatings such as copper or nickel can be applied before brazing to improve joint performance.

2. Surface Preparation Before Brazing

It is essential to thoroughly remove contaminants from the surface of the workpieces prior to brazing, including oxides, grease, dirt, and paint. Without proper cleaning, the molten filler metal cannot adequately wet the component surface, nor can it fill joint gaps. In certain cases, it may also be necessary to pre-coat parts with a specific metal layer to enhance the base material’s brazability and increase the corrosion resistance of the brazed joint.

(1) Removal of Oil Contaminants

Oil contaminants can be removed using organic solvents such as alcohol, carbon tetrachloride, gasoline, trichloroethylene, dichloroethane, and trichloroethane. For small batch production, components can be immersed in organic solvents for thorough cleaning. In large batch production, the most common method is steam degreasing. Additionally, effective degreasing can also be achieved in heated alkaline solutions; for instance, immersing steel parts in a 10% caustic soda solution at 70–80°C.

(2) Removal of Oxides

Oxides on the surface of parts prior to brazing can be eliminated using mechanical methods, chemical etching, or electrochemical etching. Mechanical methods may include files, wire brushes, sandpaper, grinding wheels, and sandblasting to remove oxide films. Files and sandpaper are typically used for single-piece production, as they create grooves advantageous for the wetting and spreading of the filler metal. For batch production, sanders, wire brushes, and sandblasting methods are more efficient. Mechanical cleaning methods are not suitable for aluminum alloys and titanium alloys.

(3) Coating Base Material with Metal

Applying a metal coating on the base material’s surface primarily aims to improve the brazability of certain materials and enhance the wettability of the filler metal. This process can also prevent adverse interactions between the base material and the filler metal that could degrade joint quality, such as crack formation or the development of brittle intermetallic compounds. It can also serve as a filler layer to simplify assembly and improve productivity.

3. Brazing Materials

(1) Filler Metals

Common filler metals include pure copper, copper-zinc alloys, and silver-copper alloys. Pure copper offers excellent wettability with various tungsten carbide materials but must be brazed in a hydrogen-reducing atmosphere to achieve optimal results. However, due to the high brazing temperature, the resulting thermal stress at joints can increase the likelihood of cracking. Traditional pure copper brazed joints have a shear strength of approximately 150 MPa, with fairly high ductility, but they are not suitable for high-temperature applications.

Copper-zinc fillers are the most widely used for brazing tungsten carbide and tool steels. To enhance the wetting capability and joint strength, alloying elements such as Mn, Ni, and Fe are often added. For example, in B-Cu58ZnMn, with a manganese content of approximately 4 wt%, the shear strength of the tungsten carbide brazed joint can reach 300–320 MPa at room temperature, maintaining 220–240 MPa at 320°C. Adding a small amount of cobalt to B-Cu58ZnMn can elevate the shear strength to 350 MPa while also providing higher impact toughness and fatigue resistance, significantly extending the service life of cutting tools and rock drill bits.

Silver-copper fillers have a lower melting point, resulting in minimal thermal stress and a lower tendency for cracking during tungsten carbide brazing. To improve wettability and enhance joint strength and operating temperatures, alloying elements such as Mn and Ni are commonly incorporated. For example, B-Ag50CuZnCdNi fillers exhibit excellent wettability with tungsten carbide and provide desirable overall performance for brazed joints.

For applications above 500°C with high joint strength demands, manganese-based and nickel-based fillers such as B-Mn50NiCuCrCo and B-Ni75CrSiB can be selected. Specific filler materials that match the quenching temperatures are required when brazing high-speed steel, divided into two categories: manganese-iron-based fillers primarily composed of manganese iron and borax, which generally yield a shear strength of around 100 MPa, although these joints are prone to cracking. The other category comprises special copper alloys containing Ni, Fe, Mn, and Si, which minimize cracking tendencies and achieve shear strengths of up to 300 MPa.

(2) Flux and Protective Gases

The selection of flux should align with both the base material and the chosen filler metal. For brazing tool steels and tungsten carbide, the primary fluxes used are borax and boric acid, often supplemented with various fluorides (KF, NaF, CaF2, etc.). Copper-zinc fillers are typically paired with FB301, FB302, and FB105 fluxes, while silver-copper fillers may utilize FB101 to FB104 fluxes. When using specialty fillers for brazing high-speed steel, borax fluxes are predominantly employed.

To prevent oxidation of tool steel during the heating process and to eliminate post-brazing cleaning, gas shielded brazing can be employed. Protective gases can either be inert or reducing gases, with the requirement that the gas dew point be below -40°C. Tungsten carbide can be brazed under hydrogen protection, necessitating a hydrogen dew point below -59°C.

4. Brazing Processes

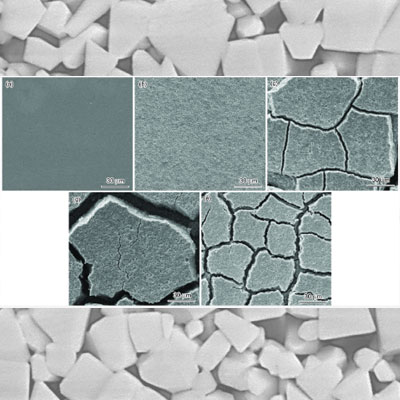

Brazing carbon tool steels requires careful surface cleaning, and the mechanical surfaces need not be overly smooth, as this aids the wetting and spreading of the materials and the flux. The surface of tungsten carbide usually requires sandblasting or grinding with silicon carbide or diamond wheels to remove excessive carbon for better wetting by the filler metal. Carbide-titanium tungsten carbide presents challenges in wetting; therefore, applying a paste of copper or nickel oxide to their surface and heating in a reducing atmosphere promotes effective wettability.

Brazing carbon tool steels is best performed prior to quenching or simultaneously with this process. If brazing occurs before quenching, the solidus temperature of the filler metal must exceed the range of the quenching temperature, ensuring the joined pieces retain sufficient strength when reheated to quenching temperatures. When brazing and quenching are performed concurrently, a filler metal with a solidus temperature close to the quenching temperature should be selected.

The composition range for alloy tool steels is broad, necessitating specific filler metal and heat treatment process selections according to the particular steel type to achieve optimal joint performance.

For high-speed steel, the quenching temperature generally exceeds the melting temperatures of silver-copper and copper-zinc fillers, necessitating pre-quenching. Brazing can be undertaken during secondary tempering or afterwards. If post-brazing quenching is required, only specialized fillers mentioned earlier should be utilized. When brazing high-speed steel tools, using a coke furnace can be quite effective; after the filler melts, the cutting tool should be removed, excess filler pressed out, then subjected to oil quenching, followed by tempering at 550–570°C.

When brazing tungsten carbide blades to steel tool bodies, methods such as increasing the gap in the brazing seam and adding a plastic compensating shim should be employed, along with post-welding slow cooling to reduce thermal stresses and prevent crack formation, thereby extending the service life of the tungsten carbide cutting tool assembly.

5. Post-Brazing Cleaning

Residues from fluxes can be corrosive to brazed joints and hinder the inspection of the joint, so they must be thoroughly removed. Initially, residual flux on the workpieces can be rinsed with hot water or a general flux-removal mixture, followed by treatment with appropriate acid cleaning solutions to eliminate the oxide layer from the base material. It is critical to avoid using nitric acid solutions to prevent corrosion of the brazed metal. Residues from organic soft fluxes can be cleaned with solvents such as gasoline, alcohol, or acetone, while corrosive residues like zinc oxide and ammonium chloride should be cleaned in a 10% NaOH solution, followed by rinsing with hot or cold water. Residues from borax and boric acid fluxes can generally be resolved using mechanical methods or prolonged boiling in water.

6. Inspection of Brazing Quality

Methods for inspecting brazed joints can be divided into nondestructive testing and destructive testing. The following highlights the nondestructive inspection methods:

- Visual Inspection

- Dye Penetrant and Fluorescent Testing: These methods primarily enable the detection of small cracks, porosity, or other defects that may not be visible through visual inspection.

This comprehensive analysis emphasizes the critical issues and solutions in tungsten carbide brazing, aiding in the understanding and enhancement of overall joint performance and quality.