how high precision wire rod rolling carbide rolls can improve your product quality and reduce your costs

How High Precision Wire Rod Rolling Carbide Rolls Can Improve Your Product Quality and Reduce Your Costs

If you are in the business of producing wire rods or rebar, you know how important it is to have high quality and consistent products that meet your customers’ expectations and specifications. You also know how challenging it is to achieve this while reducing your production costs and increasing your efficiency.

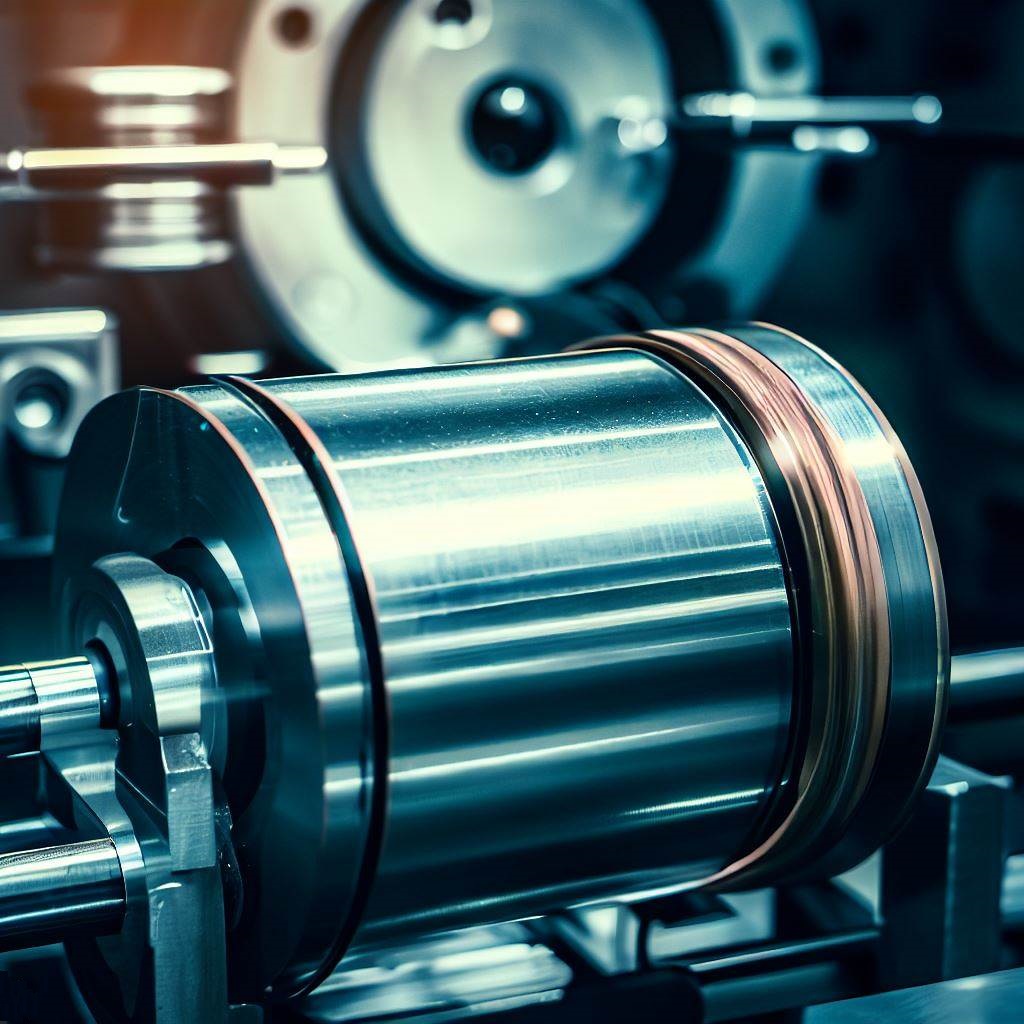

One of the key factors that affect your product quality and costs is the type of rolls you use in your wire rod rolling mill. The rolls are subjected to severe thermo-mechanical fatigue, impact, wear and corrosion during the rolling process. Therefore, you need rolls that can withstand these harsh conditions and deliver optimal performance.

This is where high precision wire rod rolling carbide rolls come in. These are rolls made of cemented tungsten carbide, a material that has excellent properties for wire rod rolling applications. In this article, we will explain how high precision wire rod rolling carbide rolls can improve your product quality and reduce your costs.

What are High Precision Wire Rod Rolling Carbide Rolls?

High precision wire rod rolling carbide rolls are rolls that are manufactured from cemented tungsten carbide grade tailored for the demanding environments of hot mills that produce wire rods and rebar. Cemented tungsten carbide is a composite material that consists of hard tungsten carbide particles embedded in a ductile metal binder, usually cobalt, nickel or iron.

The properties of tungsten carbide depend on the binder material, the amount of binder, the grain size, shape and distribution of the tungsten carbide particles. By varying these parameters, different grades of tungsten carbide can be produced to suit different applications.

High precision wire rod rolling carbide rolls are designed to have a high hardness, toughness, wear resistance and thermal conductivity. They can also be customized to have different shapes and sizes according to your specific needs and requirements.

How do High Precision Wire Rod Rolling Carbide Rolls Improve Your Product Quality?

High precision wire rod rolling carbide rolls can improve your product quality in several ways:

– They can reduce the surface defects and dimensional deviations of your wire rods or rebar by providing a smooth and uniform contact with the work material.

– They can maintain their shape and size better than conventional steel rolls, which tend to deform and wear out faster under high temperature and pressure.

– They can reduce the friction and heat generation during the rolling process, which can affect the metallurgical properties and mechanical characteristics of your products.

– They can prevent the pick-up of work material on the roll surface, which can cause contamination and deterioration of your products.

By using high precision wire rod rolling carbide rolls, you can produce wire rods or rebar that have a better surface finish, higher strength, ductility and fatigue resistance, and lower residual stresses.

How do High Precision Wire Rod Rolling Carbide Rolls Reduce Your Costs?

High precision wire rod rolling carbide rolls can reduce your costs in several ways:

– They can last up to 50 times longer than conventional steel rolls, which means you can save on roll replacement and maintenance costs.

– They can increase your productivity and efficiency by allowing you to roll at higher speeds and with fewer passes.

– They can reduce your energy consumption by lowering the heat loss and friction during the rolling process.

– They can reduce your scrap rate by minimizing the waste and rework caused by defective products.

By using high precision wire rod rolling carbide rolls, you can lower your total cost of ownership and improve your profitability.

Where Can You Find High Precision Wire Rod Rolling Carbide Rolls?

If you are looking for high quality and reliable high precision wire rod rolling carbide rolls, you can contact us. We have extensive experience and expertise in designing, manufacturing and servicing high precision wire rod rolling carbide rolls that meet your specific needs and requirements.

Conclusion

High precision wire rod rolling carbide rolls are a smart investment for any wire rod or rebar producer who wants to improve their product quality and reduce their costs. They offer superior performance, durability and efficiency compared to conventional steel rolls. They can help you achieve higher customer satisfaction and loyalty, as well as higher market share and competitiveness.