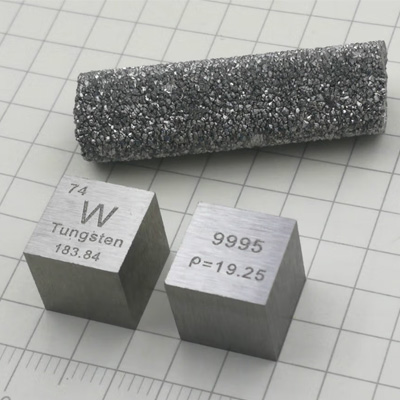

Application of Tungsten

Tungsten has the highest melting point of all metallic elements, a high density (19.3 G/cm ³), close to that of gold, and a high hardness, such as that of tungsten carbide, close to that of diamond. In addition, tungsten also has good electrical and thermal conductivity, small expansion coefficient and other characteristics, so it is widely used in alloys, electronics, chemical industry and other fields, of which cemented carbide is the largest consumption area of tungsten.

Alloy field

Steel

The hardness of tungsten is very high, and its density is close to that of gold, so tungsten can improve the strength, hardness and wear resistance of steel. It is an important alloy element and is widely used in the production of various steels. Common steels containing tungsten are high-speed steel, tungsten steel and tungsten-cobalt magnetic steel with high magnetization and coercive force. These steels are mainly used to manufacture various tools. Uch as drill bits, milling cutters, wire drawing dies, female dies and male dies.

Tungsten carbide-based cemented carbide

Tungsten carbides are often used in some cemented carbides because of their high wear resistance and refractoriness, and their hardness is close to that of diamond. At present, tungsten carbide based cemented carbide is the largest consumption field of tungsten. This kind of cemented carbide is a powder metallurgy product sintered by tungsten carbide micron powder and metal binder (such as cobalt, nickel, molybdenum) in vacuum furnace or hydrogen reduction furnace.Tungsten carbide-based cemented carbides can be generally divided into four categories: tungsten carbide-cobalt, tungsten carbide-titanium carbide-cobalt, tungsten carbide- titanium carbide- tantalum (niobium) -cobalt and steel-bonded cemented carbides, which are mainly used to manufacture cutting tools, mining tools and wire drawing dies.。Heat resistant and wear resistant alloy• Tungsten has the highest melting point of all metals and high hardness, so it is often used to produce heat-resistant and wear-resistant alloys, such as alloys of tungsten and chromium, cobalt and carbon, which are often used to produce high-strength and wear-resistant parts such as valves and turbine wheels of aero-engines. Alloys of tungsten and other refractory metals, such as tantalum, niobium, molybdenum, and rhenium, are often used to produce parts with high thermal strength, such as nozzles and engines of aerospace rockets.

High specific gravity alloy

Due to its high density and high hardness, tungsten is an ideal material for making heavy alloys. These heavy alloys are classified into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag and other major series according to their composition characteristics and applications. This kind of alloy has the characteristics of large specific gravity, high strength, strong ability to absorb rays, large thermal conductivity, small thermal expansion coefficient, good electrical conductivity, good weldability and processability.It is widely used in aerospace, aviation, military, oil drilling, electrical instrumentation, medicine and other industries, such as the manufacture of armor, heat sinks, balance weights for rudder control, and contact materials such as knife switches, circuit breakers, spot welding electrodes and so on.

Electronic field

Tungsten and its alloys are widely used in the electronics and power supply industries because of their plasticity, low evaporation rate, high melting point and strong electron emission ability. For example, tungsten filament has high luminous efficiency and long service life, so it is widely used in the manufacture of various bulb filaments, such as incandescent lamps, iodine-tungsten lamps, etc. Tungsten filament can also be used in the manufacture of direct heating cathodes and grids of electronic oscillating tubes and side heating cathode heaters in various electronic instruments. The properties of tungsten make it also suitable for TIG welding and other electrode materials for similar work.

Chemical field

Tungsten compounds are often used as catalysts and inorganic colors, such as tungsten disulfide, which is used as a lubricant and catalyst in the preparation of synthetic gasoline, bronze-colored tungsten oxide, which is used in painting, and calcium or magnesium tungsten, which are often used in phosphors.

Other Application

Tungsten is used as a glass or metal seal because its thermal expansion is similar to borosilicate glass. Tungsten has low sensitivity, so it is used to make high purity tungsten gold jewelry. In addition, tungsten is also used in radioactive medicine, and some musical instruments also use tungsten wires.